What Are the Benefits of Using a Laser Cutting Machine?

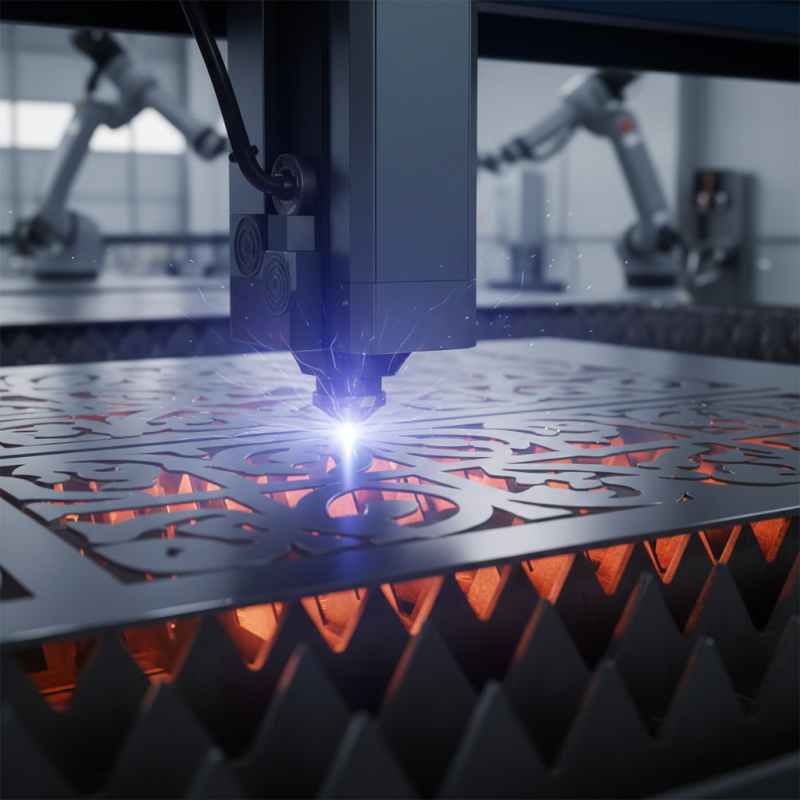

In recent years, the use of a laser cutting machine has transformed various industries. This innovative technology offers precision and efficiency that traditional methods struggle to match. By harnessing intense laser beams, users can cut through materials like metal, wood, and plastic with ease.

The benefits of employing a laser cutting machine are evident. For instance, it allows for intricate designs that were once difficult to achieve. Additionally, it reduces material waste, which is crucial in today's eco-conscious market. However, not all businesses have accessed this technology yet. A steep initial investment could deter smaller companies.

Many users report a learning curve associated with this equipment. Understanding the machine's capabilities and settings is vital for maximizing its potential. While laser cutting machines are powerful tools, improper usage can lead to unexpected results. As industries continue to evolve, reflecting on these challenges and recognizing the benefits of laser cutting machinery can drive technological advancement.

Overview of Laser Cutting Technology and Its Applications

Laser cutting technology has revolutionized manufacturing. It uses focused laser beams to cut materials precisely. Common materials include metals, plastics, and wood. According to a recent industry report, the global laser cutting market is expected to surpass $5 billion by 2025. This significant growth highlights the technology's increasing versatility and adoption across various sectors.

Applications of laser cutting vary widely. In the automotive industry, it is used for intricate parts. Aerospace manufacturers rely on laser cutting for lightweight components that require precision. A study by the Manufacturing Institute found that laser cutting can reduce production times by up to 25%. However, not all materials perform equally well with this technology, leading to questions about its efficiency in specific cases.

Some challenges persist. Understanding the right settings is crucial to avoid issues like melting or excessive burns on certain materials. Operators must frequently adjust parameters to achieve desired results. The learning curve can be steep but rewarding. With continuous advancements, laser cutting remains a topic of reflection for many in the industry.

What Are the Benefits of Using a Laser Cutting Machine?

| Dimension | Description | Application |

|---|---|---|

| Precision | Laser cutting can achieve intricate designs with high precision, making it ideal for detailed work. | Jewelry design, electronics, and prototyping. |

| Speed | Laser cutting operates at high speeds, reducing the time required for projects. | Mass production and large-scale manufacturing. |

| Material Versatility | Allows for cutting a variety of materials, including metals, plastics, and wood. | Furniture design, automotive parts, and signage. |

| Reduced Waste | Laser cutting minimizes waste due to its high precision. | Eco-friendly manufacturing practices. |

| Automation Friendly | Easily integrated into automated manufacturing processes. | Factory automation and robotics. |

Precision and Accuracy in Laser Cutting Processes

Laser cutting has revolutionized the manufacturing industry by providing exceptional precision and accuracy. Unlike traditional cutting methods, laser cutting machines use focused beams of light to achieve clean, detailed cuts. According to a study by MarketsandMarkets, the laser cutting machine market is expected to reach $9.2 billion by 2026. This growth highlights the effectiveness of this technology in various applications, from automotive to aerospace.

One key advantage of laser cutting is its ability to produce minimal kerf widths. This means that there is less wasted material, which can save businesses significant costs. Additionally, the precision of laser cutting allows for intricate designs that are often impossible with other methods. This quality can enhance product aesthetics and functionality. However, not all designs translate well. It is crucial to reconsider designs for laser compatibility.

Tip: Always prototype your designs before mass production. A small adjustment can yield better results. Every piece cut might have a slight variation, which can impact the final product. Regular maintenance of the laser cutting machine is also vital, as it can influence accuracy over time. Remember, precision is not just about the machine; it's about continuous improvement in processes.

Cost-Effectiveness and Efficiency of Laser Cutting Machines

Laser cutting machines offer significant cost-effectiveness and efficiency benefits. They provide quicker turnaround times for production. This speed can reduce labor costs and increase output. Moreover, their precision minimizes material waste. This means more complete use of raw materials, which is crucial for budget management.

In many scenarios, companies find they save money on energy. Laser cutting machines typically use less power compared to traditional methods. However, initial investment can be high. This aspect may deter some businesses from switching over. Yet, those who embrace the technology report lower costs in the long run.

Precision is essential, but it comes with challenges. A small error can lead to costly mistakes. Maintaining the machine is also necessary and can be overlooked. Companies often regret not accounting for these factors when budgeting. It's essential to weigh the initial costs against the potential savings and efficiency gained.

Versatility in Material Compatibility of Laser Cutters

Laser cutting machines offer remarkable versatility in material compatibility, making them invaluable in various industries. They can process metals, plastics, wood, acrylic, and textiles effectively. According to a report by MarketsandMarkets, the laser cutting market is projected to reach $5.28 billion by 2026, highlighting the growing demand for flexible material applications.

One significant benefit of laser cutting is its precision across different materials. For instance, a CO2 laser can cut acrylic with clean edges, while fiber lasers excel at cutting metals like stainless steel. This flexibility allows manufacturers to streamline their processes. However, it's important to recognize that not all materials react identically to laser cutting. Some materials may warp or discolor, necessitating trial runs.

Moreover, the choice of material affects production time. For example, cutting through thicker metals takes longer and may lead to heat distortion. Industry professionals often have to balance speed and quality. Understanding the nuances of each material is crucial for optimal results. Mistakes can lead to waste and increased costs, emphasizing the need for careful planning and material selection.

Environmental Benefits of Using Laser Cutting Technology

Laser cutting technology offers significant environmental benefits that are worth exploring. One of the most notable advantages is its energy efficiency. Unlike traditional methods, laser cutting requires less energy to operate. This reduces the overall carbon footprint of the manufacturing process. By using less power, businesses can minimize their environmental impact while maintaining high precision.

Another key benefit is the reduction of waste material. Laser cutting is highly accurate, which means it generates less scrap compared to conventional cutting techniques. This precision allows for better raw material utilization, leading to fewer resources being consumed. However, it's important to keep in mind that not all materials are equally eco-friendly. Some may still produce harmful emissions during processing, prompting a need for continuous improvement in material choices.

Despite these benefits, there are challenges with laser cutting technology. For instance, the initial investment in equipment can be steep. Smaller businesses might find it hard to justify such costs. Additionally, the need for skilled operators remains a concern. As technology evolves, ongoing training is essential to ensure the workforce adapts effectively. Balancing these factors is crucial for maximizing the environmental advantages of laser cutting.

English

English  Français

Français