Top 10 Benefits of Using CNC Plasma Cutting Machines?

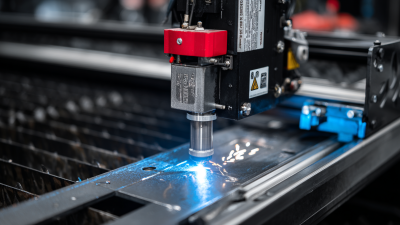

In the fast-evolving world of manufacturing, the role of CNC plasma cutting machines cannot be overstated. According to a recent industry report by Technavio, the global CNC plasma cutting machine market is expected to grow by over 10% annually through 2025. This remarkable growth is driven by the efficiency and precision these machines bring to metal fabrication processes. Dave Johnson, a leading expert in CNC technologies, states, "CNC plasma cutting machines revolutionize the way industries approach metal cutting, pushing efficiency to new heights."

The advantages of incorporating CNC plasma cutting machines in various industries are numerous. They offer remarkable speed, versatility, and minimal waste, which are crucial for maintaining competitive edges. However, challenges still exist. The initial investment can be significant, and operators need specialized training. This raises questions about accessibility for smaller businesses. Despite these hurdles, the benefits often outweigh the drawbacks, paving the way for significant advancements in production capabilities.

Industries are gradually recognizing the potential of CNC plasma cutting machines. The combination of speed and accuracy reduces turnaround times. Yet, it is essential to consider ongoing maintenance and operator proficiency as possible limitations. As we explore the top benefits of these machines, it is clear that they play a pivotal role in shaping the future of metalworking. Embracing their capabilities could redefine operational efficiency for many businesses.

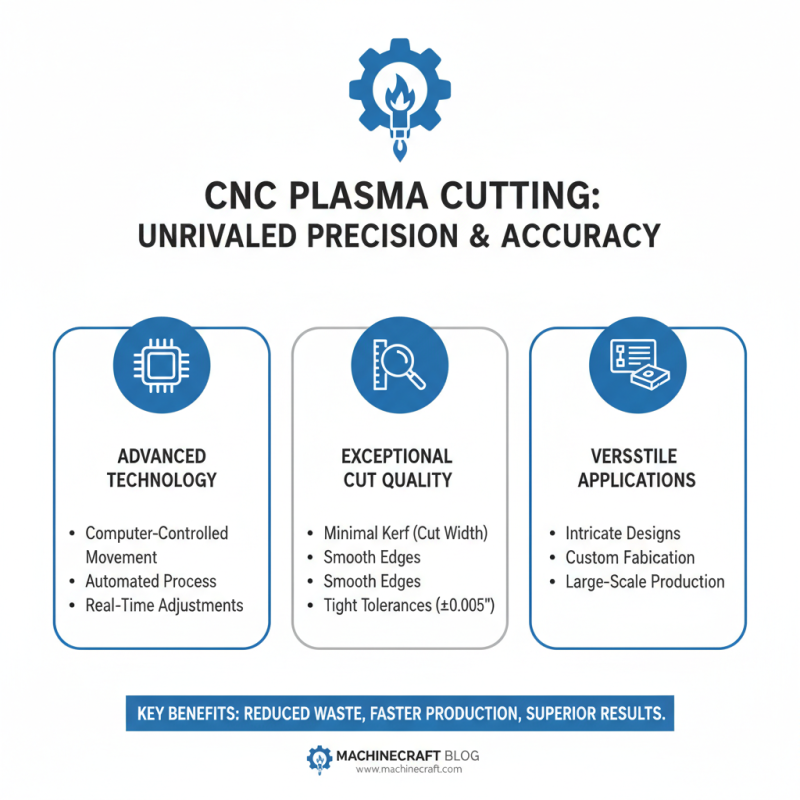

Benefits of Precision and Accuracy in CNC Plasma Cutting

Precision and accuracy are crucial in CNC plasma cutting. These machines utilize advanced technology to achieve remarkable cutting capabilities. As such, they deliver intricate designs with minimal deviations. Every detail is captured, whether it's for custom fabrication or large-scale production runs.

With CNC plasma cutting, even the most complex shapes can be cut effortlessly. The ability to program precise measurements means that each piece fits perfectly. This eliminates the frustration of mismatched parts. However, operators must stay vigilant. Minor errors in input can lead to significant setbacks. Thus, continuous vigilance is essential.

Moreover, the speed of CNC plasma cutting enhances productivity. Yet, fast doesn't always mean flawless. Operators can sometimes sacrifice quality for speed. Balancing efficiency and meticulousness remains a challenge. This fine line is crucial for achieving desired outcomes while maintaining high standards.

Increased Production Efficiency with CNC Plasma Technology

CNC plasma cutting machines are transforming the manufacturing landscape. They significantly enhance production efficiency. This technology allows for precise cuts in various materials. As a result, manufacturers can save time and reduce waste.

One of the main advantages is speed. CNC plasma cutting can perform intricate cuts quickly. This rapid production lowers lead times. It allows businesses to take on more projects simultaneously. However, operators must be trained well to maximize these benefits. There's a learning curve that can slow down initial production.

Tip: Always ensure your plasma cutting machine is well-maintained. Regular checks can prevent unexpected delays. Also, employ skilled workers who understand CNC operations. Mistakes can lead to material waste and increased costs. Investing in training pays off in the long run. Workers who are adept at the machine create higher quality products with fewer errors.

By utilizing CNC plasma technology, businesses can maintain competitiveness. Still, it’s essential to continually evaluate production processes. Efficiency is not just a goal; it's an ongoing effort. Adjustments may be necessary as the market evolves, and technology advances.

Versatility of Materials Cut by CNC Plasma Machines

CNC plasma cutting machines offer incredible versatility when it comes to materials. These machines can cut through steel, aluminum, brass, and even some types of plastics. This capability makes them ideal for various industries, from automotive to aerospace. The precision of plasma cutting allows for intricate designs and clean edges. You can achieve complex geometries that traditional cutting methods often struggle with.

However, not all materials react the same way. Some metals may warp or discolor due to high temperatures. It's crucial to understand material characteristics before cutting. Additionally, the thickness of the material matters. Plasma cutting is effective for thin to medium thicknesses but becomes less efficient for thicker materials. Experimentation may lead to imperfections.

Being aware of these factors can save time and resources. Understanding your project's needs ensures the best results. The beauty of CNC plasma cutting lies in both its efficiency and its inherent challenges. Embracing these challenges can lead to incredible design possibilities.

Top 10 Benefits of Using CNC Plasma Cutting Machines

| Benefit | Description | Material Compatibility |

|---|---|---|

| Precision Cutting | Provides high accuracy on intricate designs and small parts. | Steel, Aluminum, Brass |

| Speed | Fast cutting speeds reduce overall production time. | Mild Steel, Stainless Steel |

| Cost-Effective | Lower operational costs compared to traditional cutting methods. | Carbon Steel, Copper |

| Versatility | Cuts various thicknesses and materials easily. | Aluminum, Plastics |

| Minimal Material Waste | Precision cutting minimizes scrap production. | Most metals |

| Ease of Use | User-friendly software for easy operation and programming. | Aluminum, Brass, Various Alloys |

| Improved Safety | CNC machines enhance operator safety through automation. | N/A |

| Detailed Finishing | Delivers clean edges and detailed features. | Stainless Steel, Other Metals |

| Scalability | Easily adaptable for small to large scale production. | All metals, including exotic alloys |

| Eco-Friendly | Less energy consumption compared to traditional cutting methods. | N/A |

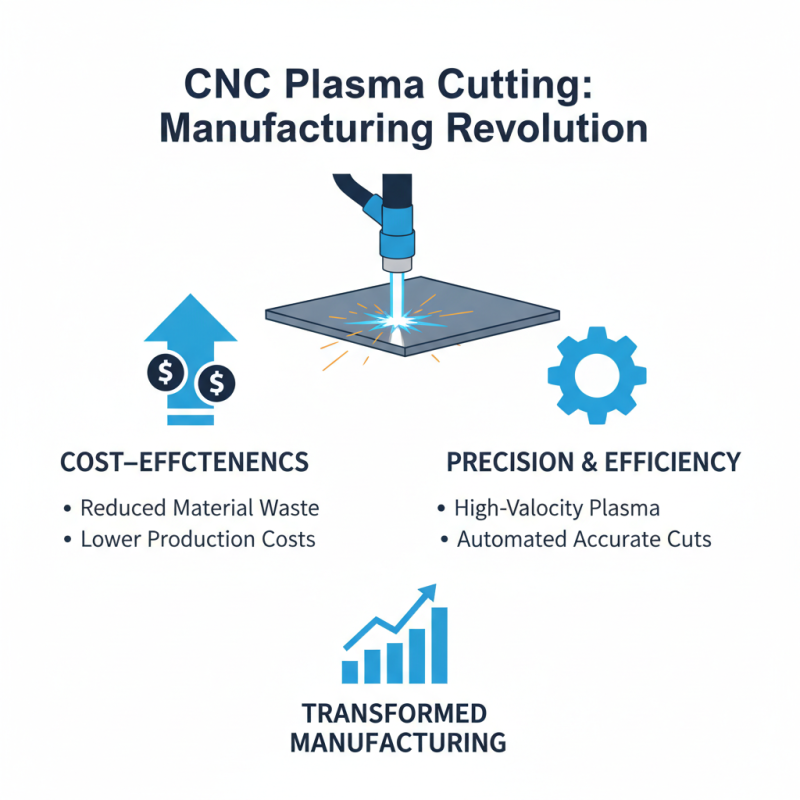

Cost-Effectiveness of Using CNC Plasma Cutting in Manufacturing

CNC plasma cutting machines have transformed manufacturing through cost-effectiveness. These machines use high-velocity plasma to cut metal, enhancing precision. As a result, they minimize material wastage. This reduces costs significantly, which is crucial in competitive markets.

Investing in CNC plasma cutting can initially seem high. However, the savings over time often outweigh setup expenses. Maintenance tends to be low, yet some may overlook this aspect. Regular care can extend the machine's life and improve cutting quality. Quick turnaround times are another asset. Projects complete faster, boosting productivity.

There are challenges to consider. Operators need training to use the machines effectively. Without proper skill, mistakes can lead to increased costs. Understanding the technology is essential for maximizing benefits. Make sure to weigh these factors before adopting the technology. Factoring in the right applications can also impact the overall efficiency.

Enhanced Safety and Reduced Operator Risk with CNC Plasma Cutting

CNC plasma cutting machines significantly enhance safety in the workplace. With automated processes, they reduce manual handling of materials. Operators can maintain a safe distance from cutting actions. This distance minimizes risks associated with traditional cutting methods.

Tips: Always wear protective gear. Eye protection is crucial. Gloves can help prevent burns. Regularly inspect your equipment, as worn parts can pose dangers.

These machines use advanced software to control movements precisely. This technology reduces the chance of human error. However, operators must remain vigilant. Distractions can lead to accidents, even with automated systems.

Tips: Stay focused during operation. If you feel fatigued, take breaks. A fresh mind ensures better concentration.

While CNC plasma cutters are safer, they still require careful handling. The machines’ high temperatures can be hazardous. Operators should maintain their workspaces to prevent accidents. Clean areas are less likely to cause injuries.

Related Posts

-

Maximizing Value with Best Metal Plasma Cutter After Sales Support and Maintenance Cost Insights

-

7 Reasons Why Cnc Plasma Cutters Are Essential for Modern Manufacturing Success

-

Envisioning the Future of Compact CNC Plasma Cutting Technology for Global Buyers

-

Maximizing Efficiency and Reducing Downtime with Cnc Plasma Cutter Maintenance Tips

-

Unlock Precision and Efficiency: Explore the Future with Plasma Laser Cutters for Modern Manufacturing

-

The Comprehensive Handbook for Sourcing Small Plasma Tables Globally

English

English  Français

Français