Ultimate Checklist for Choosing the Perfect Laser Cutting Machine for Your Business Needs

In today's fast-paced manufacturing environment, the selection of a Laser Cutting Machine is crucial for businesses looking to enhance efficiency and precision. According to a recent report by MarketsandMarkets, the global laser cutting market is projected to grow from $3.92 billion in 2021 to $5.63 billion by 2026, reflecting a CAGR of 7.7%. This surge underscores the increasing reliance on laser cutting technology across various industries, including automotive, aerospace, and textiles, due to its ability to cut complex designs with minimal material waste. As more businesses recognize the advantages of laser cutting—such as speed, accuracy, and versatility—the importance of choosing the right machine tailored to specific operational needs cannot be overstated. This ultimate checklist aims to guide you through the essential considerations for selecting a Laser Cutting Machine that aligns perfectly with your business objectives.

Factors to Consider When Evaluating Laser Cutting Machine Types for Your Business

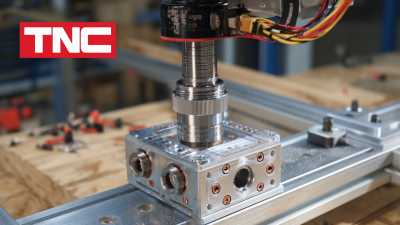

When evaluating laser cutting machines for your business, several key factors come into play to ensure that you choose the right one for your specific needs. First, consider the materials you plan to work with; different lasers—such as CO2, fiber, and Nd:YAG—excel at cutting various materials like wood, acrylic, and metals. Understanding the compatibility of laser types with the materials you intend to utilize will help you avoid costly mistakes and ensure efficiency.

Next, assess the machine's power and speed. Higher wattage lasers can cut through thicker materials and operate faster, which is essential for production environments where time and throughput are critical. Additionally, think about the size of the work area; if your projects involve large sheets or complex designs, a machine with a larger cutting bed is necessary. Finally, don’t overlook software compatibility and support. A user-friendly interface with robust design software integration can greatly enhance your operational workflow, making it easier to produce high-quality results consistently. Choosing the right laser cutting machine involves a careful evaluation of these factors to align with your business objectives and maximize productivity.

Understanding the Different Laser Cutting Technologies: CO2 vs. Fiber Laser

When considering laser cutting technologies for your business, understanding the differences between CO2 and fiber lasers is crucial. CO2 lasers have been a staple in the industry since their introduction in the 1980s, offering great versatility for cutting various materials, particularly in thicker sections of metal. They operate typically at power outputs ranging from 2.2 to 6 kW, making them suitable for a wide range of applications. Yet, as the market evolves, fiber lasers are increasingly gaining traction due to their higher efficiency and faster cutting speeds. Reports indicate that fiber lasers offer a cutting speed that can be up to 25% faster than CO2 lasers, significantly boosting productivity in metal fabrication.

The laser processing market is forecasted to witness substantial growth from 2025 to 2030, driven by advancements in laser technology and increasing demand from diverse sectors. Specifically, fiber laser machines are expected to dominate, thanks to their lower operational costs and enhanced performance. Unlike CO2 lasers, which demand more maintenance, fiber lasers have a robust design that reduces downtime, resulting in lower long-term operational costs. Consequently, businesses must weigh these factors carefully to ensure they choose the most suitable technology for their specific manufacturing needs.

Key Industry Performance Metrics: Speed, Accuracy, and Material Compatibility

When selecting the perfect laser cutting machine for your business, understanding key industry performance metrics is essential. Speed is one of the most critical factors; high-performance laser cutters can achieve speeds of up to 120 inches per second. According to a 2022 report from the Laser Institute of America, machines with advanced optics and control systems can reduce processing time by as much as 30%, substantially increasing productivity in a competitive market.

Accuracy is another pivotal aspect, particularly for industries requiring intricate designs, such as aerospace and automotive. Lasers can deliver cutting tolerances down to ±0.001 inches, surpassing traditional cutting methods. The Precision Metalforming Association highlights that businesses employing high-accuracy laser machines see a 20% reduction in material waste, contributing directly to profit margins.

Material compatibility also plays a critical role in machine selection. The versatility of a laser cutting machine affects its usability across various applications, from metal and plastics to wood and textiles. Industry studies indicate that machines with multi-material capabilities are preferred by 70% of manufacturers, as they can adapt to evolving market demands and expand product offerings without investing in multiple machines. This adaptability ensures businesses remain agile and responsive to customer needs.

Cost Analysis: Balancing Initial Investment and Long-term Operational Expenses

When considering the perfect laser cutting machine for your business, a thorough cost analysis is essential. Businesses often balance the initial investment against long-term operational expenses to ensure the technology aligns with their financial goals. The rapidly changing economic landscape, influenced by advanced technologies such as AI, emphasizes the need for a strategically sound investment. For instance, as companies invest significantly in data center infrastructures to support AI capabilities, understanding the total cost of ownership—including maintenance, energy consumption, and potential productivity gains—becomes increasingly critical.

Additionally, energy efficiency will play a pivotal role in determining long-term costs. In today's environment, organizations are seeking sustainable solutions that not only reduce upfront costs but also minimize ongoing operational expenditures. This extends to utilizing energy-efficient technologies and renewable energy systems, which can mitigate risks associated with fluctuating energy prices. These factors underscore the importance of not only choosing a laser cutting machine based on its features but also evaluating its economic impact, thereby ensuring that your choice contributes to both productivity and sustainability in your business operations.

Future-Proofing Your Investment: Trends in Laser Cutting Technology and Automation

As businesses seek to enhance their operations, investing in laser cutting technology has become pivotal. In the face of ongoing supply chain disruptions projected for 2024, companies must future-proof their investments by keeping abreast of emerging trends within laser cutting and automation. The shift towards advanced automation solutions can significantly improve efficiency, with industry studies indicating that automated laser cutting can enhance production speed by up to 50%, reducing lead times and costs.

Moreover, sustainability is shaping the landscape of laser cutting technology. Reports suggest that eco-friendly practices, such as energy-efficient machines and recyclable materials, are increasingly favored by manufacturers and consumers alike. By adopting these technologies, businesses not only comply with regulatory standards but also meet the growing demand for sustainable practices, which 70% of consumers are now prioritizing in their purchasing decisions. Engaging with cutting-edge laser cutting machines that incorporate these trends will undoubtedly position businesses favorably in an evolving market, ensuring their readiness to tackle future challenges in the supply chain and beyond.

Ultimate Checklist for Choosing the Perfect Laser Cutting Machine for Your Business Needs

| Feature | Importance | Current Trends | Future-Proofing |

|---|---|---|---|

| Laser Type | High | Fiber Lasers gaining popularity | Invest in adaptable laser types |

| Cutting Speed | High | Increased demand for faster operations | Look for high-speed options |

| Material Versatility | Medium | Growing use of diverse materials | Choose machines with multi-material capabilities |

| Automation Features | High | Rise in automation and smart technologies | Invest in automated solutions for efficiency |

| Software Compatibility | High | Integration with design software is essential | Ensure future software upgrades are supported |

| Maintenance Support | Medium | Greater focus on reliable support | Choose vendors with strong service options |

Related Posts

-

Exploring CNC Laser Cutting Machine Applications in Diverse Industries and Their Benefits

-

Ultimate Checklist for Choosing the Best CNC Cutting Machine for Your Business Needs

-

Unlock Precision and Efficiency: Explore the Future with Plasma Laser Cutters for Modern Manufacturing

-

Unlocking Precision and Efficiency with Best Cnc Cutting Table Technical Specifications and Setup Guide

-

Unveiling the Common Challenges Faced by Manufacturers in Adopting the Best Laser CNC Technology

-

Unveiling the Best Plasma CNC Machine Options for Your Business Needs

English

English  Français

Français