How to Choose a Ball Screw for Sale in 2026?

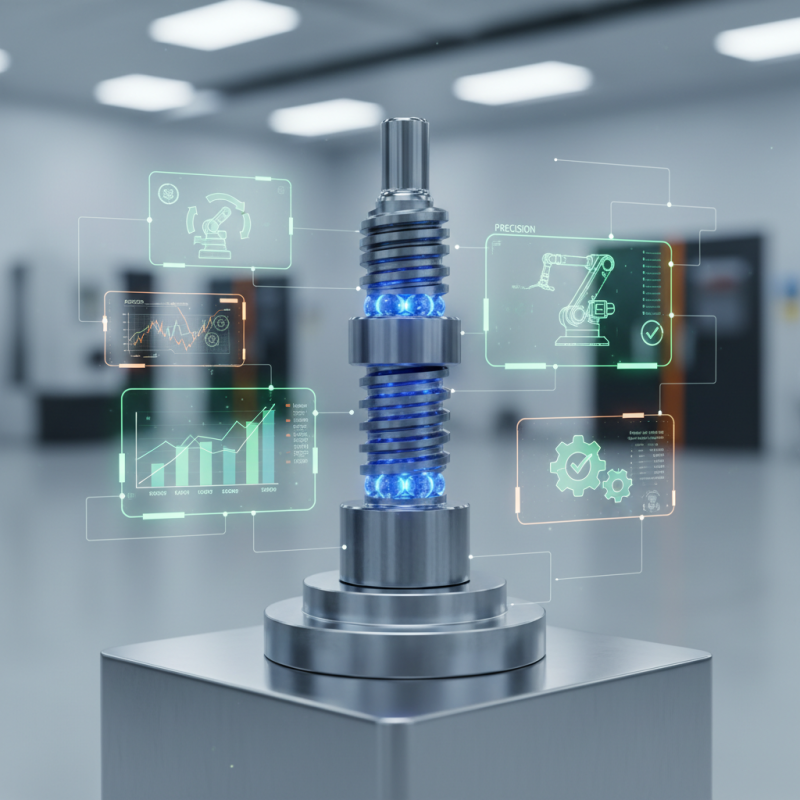

Choosing the right ball screw for sale requires careful consideration. With numerous options available, it's essential to understand your specific needs. The ball screw's design affects its performance. Precision, load capacity, and speed are critical factors to evaluate.

When searching for a ball screw for sale, think about the application. Industrial machinery or robotics may require different specifications. Key details include the screw's diameter and lead. These metrics will influence the efficiency of your machinery.

Many buyers overlook the importance of compatibility. Ensure the ball screw fits your existing system. This prevents unnecessary adjustments or replacements later. A well-chosen ball screw can enhance productivity. However, a poor choice may lead to issues. Reflecting on these aspects can lead to better purchasing decisions.

Understanding the Basics of Ball Screw Functionality and Design

When considering ball screws, understanding their functionality is crucial. A ball screw converts rotary motion into linear motion. They are used in various applications, from CNC machines to robotics. The core component is the screw and nut, which enable smooth movement. The balls within them reduce friction, enhancing performance. This functionality allows for precision and efficiency.

Design aspects are equally important. The diameter and lead of the screw affect load capacity and speed. Ensuring the correct fit is vital for optimal performance. Ball screws come in different configurations. For example, some have a preloaded design for increased rigidity. Not all designs suit every application, requiring careful evaluation. Even slight miscalculations in design can lead to significant performance issues.

Testing can reveal imperfections in design or functionality. It's essential to assess factors like load and speed before selecting a ball screw. Taking time to analyze requirements is often overlooked. Skipping this step may lead to unexpected challenges in the long run. Balancing cost and quality is also tricky. You may find cheaper options, but they might not meet your needs.

Key Specifications to Consider When Choosing a Ball Screw in 2026

When selecting a ball screw in 2026, key specifications become crucial. Load capacity stands out. A well-designed ball screw can handle loads ranging from 500 to over 10,000 Newtons. Consider the application. Higher loads require robust materials. Steel is common, but composites may offer weight savings.

Another vital factor is accuracy. Precision levels can affect performance significantly. According to industry reports, high-precision ball screws achieve tolerances as tight as 10 microns. End users must assess their requirements. Some might handle only light tasks, while others demand extreme precision. This trade-off can lead to over-engineering or suboptimal purchases.

Speed is also important. Manufacturers often report speeds exceeding 5 meters per second for certain models. However, high-speed applications may cause wear. Bearing life and maintenance become critical. Regular checks can prolong performance. Remember, choosing specifications isn't just numbers. Understanding real-world application makes a difference. Misjudging needs can lead to operational inefficiencies and increased costs.

How to Choose a Ball Screw for Sale in 2026? - Key Specifications to Consider When Choosing a Ball Screw in 2026

| Specification | Description | Typical Value |

|---|---|---|

| Lead Screw Diameter | The diameter of the screw which affects load capacity and stiffness. | 16 mm - 40 mm |

| Pitch | Distance traveled per rotation of the screw. | 5 mm - 20 mm |

| Load Capacity | Maximum load the screw can support without failure. | 500 N - 5000 N |

| Length | Overall length of the screw. | 100 mm - 2000 mm |

| Precision Class | The tolerance levels of the screw which affect positioning accuracy. | C7 - C10 |

| Material | Material used for manufacturing the screw which affects durability. | Steel, Stainless Steel, Alloy |

| End Machining | Customization of screw ends for mounting or connection. | Standard, Custom |

Analyzing Load Capacity and Efficiency Ratings for Ball Screws

When selecting a ball screw in 2026, analyzing load capacity and efficiency is crucial. The load capacity often defines how well a ball screw will perform under stress. According to industry reports, the rated load capacity can vary significantly. For instance, a standard ball screw may have a load capacity ranging from 1,000 to 100,000 N, depending largely on its size and design.

Efficiency ratings are equally vital. High-efficiency ball screws can often achieve ratings over 90%. This efficiency improves energy savings and reduces wear on machinery. However, choosing a very high-efficiency screw might come with trade-offs. Sometimes, the operational lifespan can be shorter due to increased heat generation. You need to balance longevity and performance when making your choice.

Don’t overlook environmental factors. Operating conditions such as temperature and dust can affect performance. For example, a ball screw in a clean room may perform better long-term compared to one in a dirty environment. It's essential to reflect on your specific application details. A deeper understanding can lead to better decision-making.

Material Selection: Comparing Steel, Stainless Steel, and Plastics

When choosing a ball screw in 2026, material selection is crucial. Steel is a common choice due to its high strength and durability. It is cost-effective, yet it is also susceptible to corrosion. According to industry reports, about 65% of all ball screws sold are made from steel. However, they may require surface treatments to enhance corrosion resistance.

Stainless steel, while more expensive, offers superior corrosion resistance. This makes it ideal for applications in harsh environments. Studies show that around 25% of users prefer stainless steel for its longevity and reduced maintenance needs. The trade-off lies in its lower strength compared to carbon steel, which may not suit all applications.

Plastics are emerging as an alternative, particularly in low-load scenarios. They are lightweight and resistant to corrosion. Reports indicate that plastic ball screws account for about 10% of the market. However, they may lack the stability that metal counterparts provide. As a result, selecting the right material is not just about cost but also about performance expectations. Balancing these factors can be a challenge.

Industry Trends: Innovations and Sustainability in Ball Screw Technology

In 2026, the ball screw industry continues to innovate. Technology is evolving. High efficiency and sustainability are key focuses. Manufacturers are exploring new materials that reduce waste. Eco-friendly lubricants are gaining traction. These changes reflect a broader environmental consciousness.

Sustainability is not just a trend. It’s a necessity in today’s world. However, many companies struggle to balance performance and eco-friendliness. Engineers must adapt designs for better resource management. Not every innovation leads to reduced costs. Finding the right combination of durability and sustainability is challenging. Educating teams about these shifts is crucial.

Moreover, custom solutions are becoming more popular. Many industries require specific features. This can lead to higher costs and longer lead times. Flexibility in production is essential but often overlooked. The path to sustainable practices involves trial and error. The ball screw market in 2026 is a mix of potential and obstacles. Embracing change while recognizing flaws will shape the future.

English

English  Français

Français