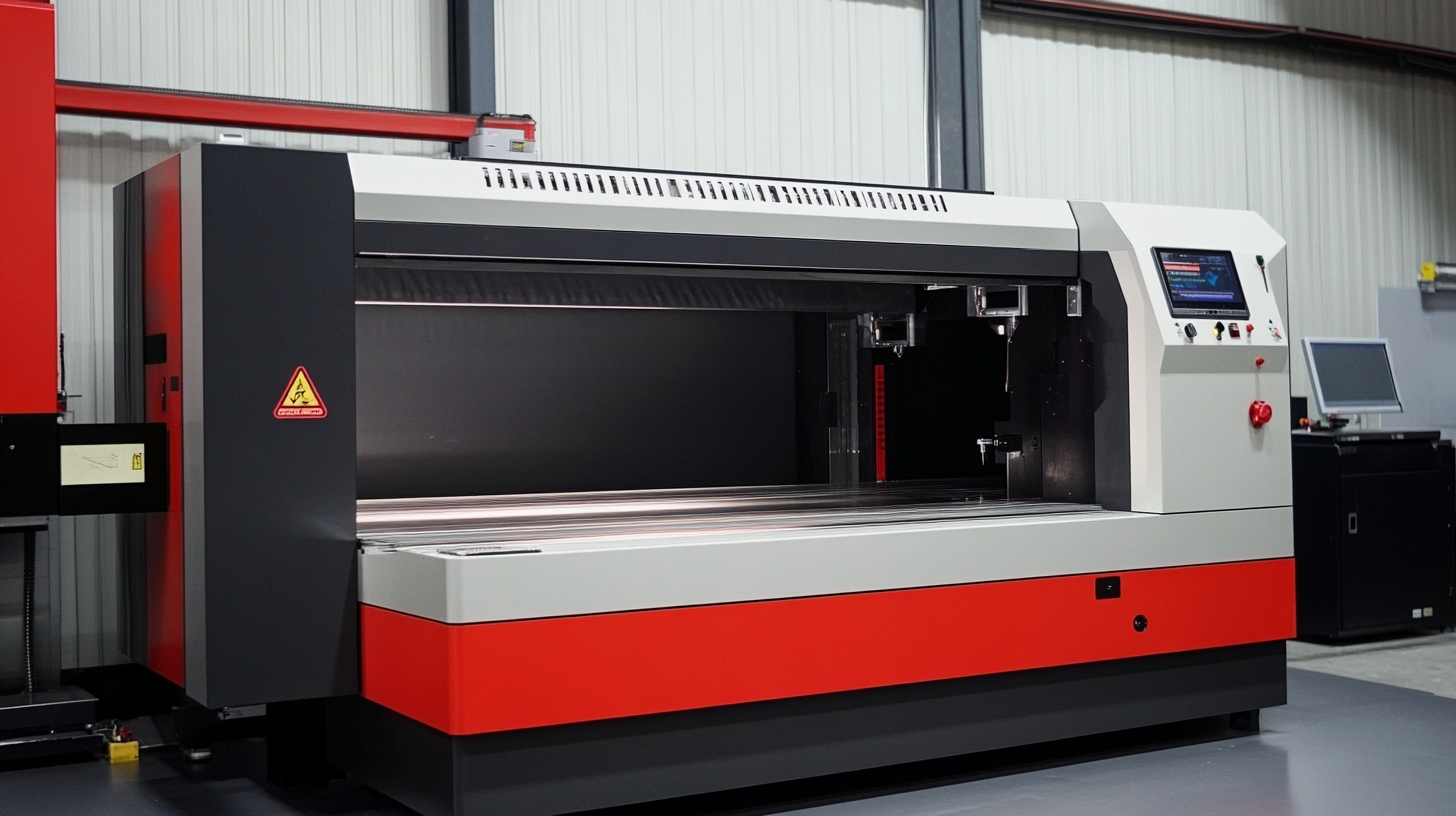

Exploring CNC Laser Cutting Machine Applications in Diverse Industries and Their Benefits

In the age of advanced manufacturing, the Cnc Laser Cutting Machine has emerged as a transformative tool across various industries. This innovative technology harnesses the precision of lasers to cut and engrave materials with unparalleled accuracy, making it an invaluable asset in sectors ranging from automotive to aerospace, electronics, and beyond. Companies are increasingly adopting CNC laser cutting for its efficiency and ability to handle complex designs that traditional cutting methods struggle with. As industries evolve, understanding the diverse applications of this technology becomes crucial for businesses looking to enhance their production capabilities.

The benefits of utilizing a Cnc Laser Cutting Machine extend far beyond mere efficiency. Not only does it offer high-speed processing and reduced material waste, but its capability to produce intricate patterns also opens up new avenues for creative design. Industries can achieve consistent quality and flexibility in their manufacturing processes, accommodating everything from prototyping to large-scale production runs. This blog will delve into the various applications of CNC laser cutting machines across different sectors, highlighting their advantages and the potential they hold for the future of manufacturing.

Overview of CNC Laser Cutting Technology and Its Mechanisms

CNC laser cutting technology has rapidly transformed various manufacturing landscapes by offering unparalleled precision and efficiency. This advanced process utilizes a focused laser beam to cut, engrave, or etch materials with remarkable accuracy. According to a report by MarketsandMarkets, the global laser cutting market is projected to reach USD 5.68 billion by 2025, growing at a Compound Annual Growth Rate (CAGR) of 5.56% from 2020. This growth can be attributed to the versatility of CNC laser cutting machines across industries such as automotive, aerospace, and electronics. The mechanism behind CNC laser cutting involves several key components, including a laser source, a CNC controller, and a highly flexible optics system. The process begins with the CNC software interpreting a design file, which directs the laser's movements and power settings to achieve precise cuts. The laser beam, generated from either CO2 or fiber optics, is then directed through a lens to focus on the material surface, leading to its vaporization or melting. Studies indicate that this technology can reduce material waste by up to 20%, significantly enhancing operational efficiency. Furthermore, CNC laser cutting machines offer the ability to work with a wide range of materials, including metals, plastics, wood, and textiles. This versatility illustrates their pivotal role in industries requiring intricate designs and high-quality finishes. A study from Allied Market Research highlights that the increasing demand for lightweight materials in the aerospace sector leads to a growing adoption of laser cutting, as it can handle composite materials that traditional methods often struggle with. This adaptability not only streamlines production but also positions companies to meet the dynamic demands of the market.

Key Applications of CNC Laser Cutting in the Manufacturing Sector

CNC laser cutting technology has revolutionized the manufacturing sector, offering precision and versatility across various applications. One prominent application is in the automotive industry, where manufacturers utilize CNC laser cutting to create intricate parts with minimal waste. This method allows for the rapid prototyping of components, leading to faster turnaround times and improved efficiency in production lines. With the ability to cut through materials such as steel, aluminum, and composites, CNC laser cutting ensures that manufacturers can meet the demanding specifications of modern vehicles.

Another key application is in the fabrication of metal and sheet materials. Industries such as construction and aerospace benefit from laser cutting’s ability to produce complex shapes and designs that are often challenging to achieve with traditional cutting methods. The high level of detail and edge quality provided by CNC laser cutting minimizes the need for secondary operations, significantly streamlining the manufacturing process. This not only reduces production costs but also enhances the overall quality of the finished products.

Moreover, CNC laser cutting is increasingly used in the electronics industry for precise circuit board fabrication. This technology allows for tightly packed components and intricate patterns, which are essential for modern electronic devices. The flexibility of laser cutting enables manufacturers to easily adapt designs to new specifications without extensive retooling, thus supporting innovation and rapid development in this fast-paced sector. Overall, the diverse applications of CNC laser cutting in manufacturing highlight its integral role in advancing technology and enhancing operational efficiencies.

Advantages of CNC Laser Cutting for the Automotive Industry

CNC laser cutting technology has revolutionized the automotive industry, offering unparalleled precision and efficiency in manufacturing processes. One of the most significant advantages of CNC laser cutting is its ability to create complex shapes and intricate designs with minimal waste. This not only reduces material costs but also enables manufacturers to produce lightweight components that enhance fuel efficiency and overall vehicle performance. The high-speed cutting capability of lasers allows automotive companies to accelerate production timelines, meeting the growing demand for faster turnaround and innovation in vehicle designs.

Another benefit of CNC laser cutting in the automotive sector is the flexibility it provides in working with various materials. Whether it involves cutting metals, plastics, or composites, laser machines can handle a wide range of substrates, making them versatile tools in the assembly line. This adaptability allows manufacturers to experiment with new materials that can lead to improved durability and lighter vehicles, aligning with the industry's shift towards sustainability and eco-friendliness. Furthermore, the precision of CNC laser cutting ensures that components fit together perfectly, which is crucial for modern vehicles that incorporate advanced technology and intricate designs.

In addition, CNC laser cutting contributes significantly to safety and quality assurance in automotive manufacturing. The precision of the laser minimizes the potential for errors, which helps in maintaining consistent quality across produced parts. Since the cutting process produces fewer physical stresses on materials, it reduces the risk of defects and enhances the longevity of components. As automakers strive for higher safety standards and better performance, CNC laser cutting stands out as a key technology that not only meets these demands but also supports innovation and efficiency in the industry.

Innovative Uses of CNC Laser Cutting in the Medical Field

The application of CNC laser cutting technology in the medical field has transformed manufacturing processes, enabling precision and efficiency that are crucial in this industry. According to a report by MarketsandMarkets, the global laser cutting market for medical applications is expected to reach $1.23 billion by 2024, growing at a CAGR of 5.16%. This growth can be attributed to the increasing demand for advanced medical devices that require intricate designs and high accuracy.

CNC laser cutting allows for the effective production of medical components, such as surgical instruments and implants. For instance, with the ability to cut materials like stainless steel and titanium with minimal heat affected zones, manufacturers can ensure the integrity of the materials used in implants, vital for patient safety and product durability. A study published in the Journal of Manufacturing Processes highlighted that utilizing laser cutting reduced production time by up to 60%, thus accelerating the time-to-market for new medical devices, which is critical in a field that continuously innovates.

Moreover, the precision of CNC laser cutting results in reduced waste, aligning with sustainable practices increasingly prioritized in healthcare manufacturing. A report from the International Journal of Production Research indicates that using laser technology can lead to a material waste reduction of up to 30%. This not only benefits the environment but also significantly cuts costs, making it an attractive option for manufacturers. As the healthcare sector continues to evolve, the innovative applications of CNC laser cutting will undoubtedly play a pivotal role in enhancing the quality and efficiency of medical solutions.

The Future of CNC Laser Cutting: Trends and Emerging Markets

The landscape of CNC laser cutting technology is rapidly evolving, with emerging trends reshaping various industries. Recent reports indicate that the global CNC laser cutting market is projected to reach $5.67 billion by 2026, driven by advancements in laser technology and increasing demand for precision cutting across diverse sectors. Industries such as automotive, aerospace, and electronics are at the forefront, leveraging CNC laser cutting for enhanced manufacturing efficiency and cost-effectiveness.

One noteworthy trend is the growing incorporation of automation and Industry 4.0 principles. Manufacturers are increasingly integrating CNC laser cutting machines with intelligent systems and IoT capabilities. According to a recent research study, automating laser cutting processes can lead to a 30% increase in productivity while significantly reducing operational costs. As companies seek to streamline operations and reduce waste, the shift towards automated CNC laser cutting solutions is expected to gain momentum.

Moreover, the demand for customized and intricate designs is on the rise, particularly in sectors like architecture and fashion. CNC laser cutting allows for high levels of customization, enabling designers to create complex patterns and unique shapes with precision. The uptick in personalized consumer goods is projected to further fuel the growth of CNC laser cutting applications, as businesses look to meet the diverse preferences of their clientele. As these emerging markets develop, CNC laser cutting will continue to play a vital role in innovation and productivity across various sectors.

English

English  Français

Français