Mastering Cnc Plasma Table Specifications for Global Buyers Finding Your Ideal Machine in Canada

In the ever-evolving landscape of manufacturing and metal fabrication, the demand for precise and efficient cutting technologies has soared. Among these, CNC plasma tables have emerged as a game-changer, offering unparalleled accuracy and speed for a variety of applications. For global buyers, particularly those interested in CNC plasma table Canada, navigating the specifications and features of these machines can be a daunting task. Whether you're a seasoned professional or a newcomer to the industry, understanding the essentials of CNC plasma tables is crucial for making informed purchasing decisions.

This blog aims to equip you with the knowledge needed to master CNC plasma table specifications, ensuring that you find your ideal machine tailored to your specific needs. From assessing cut quality and speed to understanding the importance of software compatibility, we will delve into the core attributes that define the best CNC plasma tables available in Canada. By the end of this guide, you will be well-prepared to identify the perfect CNC plasma table that meets your operational requirements, helping you stay competitive in the global marketplace.

Understanding CNC Plasma Table Basics for International Buyers

When exploring CNC plasma tables, international buyers must first grasp the fundamental concepts that govern this technology. CNC, or Computer Numerical Control, automates the plasma cutting process, making it versatile for various materials, including steel, aluminum, and copper. According to a report by Allied Market Research, the global CNC plasma cutting machine market is projected to reach $3.5 billion by 2027, reflecting a growing demand in manufacturing sectors. A key consideration for potential buyers is the power output of plasma tables, measured in amperage. Higher amperage typically allows for thicker materials to be cut, impacting efficiency and capacity in production. Industry standards indicate that a plasma table with at least 60 amps is ideal for cutting thick metals, while those requiring precision in thin sheets may find 45 amps sufficient. Furthermore, understanding cut quality and speed—often measured in inches per minute—can greatly influence operational effectiveness. Another crucial specification is the working area. Buyers should evaluate their most common project sizes and choose a table with an appropriate bed size, as working with insufficient space can lead to operational limitations. According to a survey by IBISWorld, the demand for larger cutting areas has increased due to trends in custom fabrication and bespoke manufacturing. Thus, international buyers must assess their unique needs to optimize their investment in a CNC plasma table that aligns with their operational goals in Canada and beyond.

Key Specifications to Consider When Choosing a Plasma Table

When choosing the right CNC plasma table, several key specifications can guide global buyers, particularly those seeking machines in Canada. First and foremost, cutting thickness and speed are crucial. A high-quality plasma table should effectively handle various materials, delivering precise cuts on metals ranging from mild steel to aluminum. According to industry standards, a cutting speed of at least 10 to 15 inches per minute for thicker materials (1/2" to 1") is often a benchmark for robust machines, while thinner materials should see speeds that can exceed 100 inches per minute.

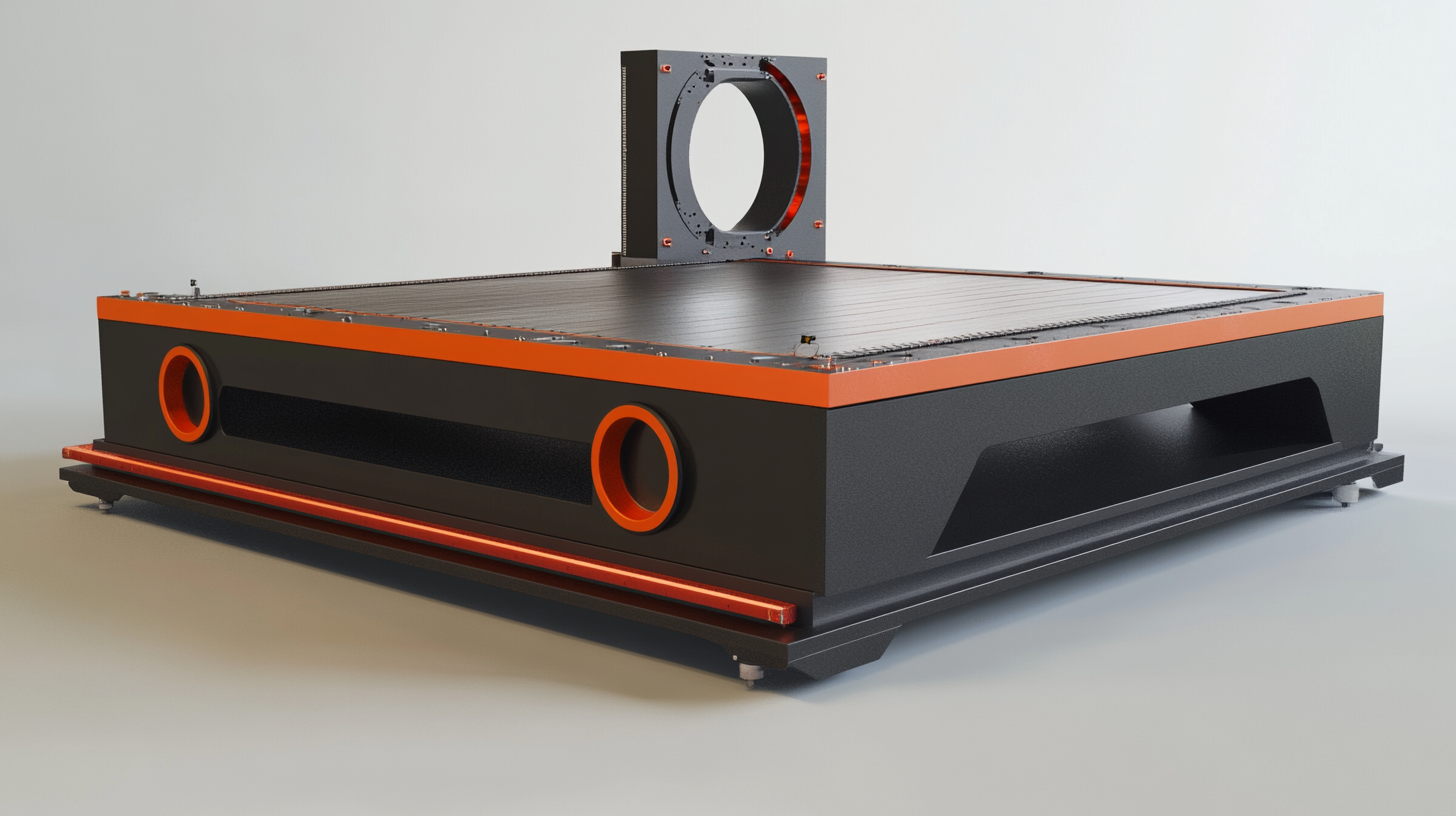

Another critical aspect is the table size and working area. Potential buyers should consider the size of the jobs they will undertake. A typical CNC plasma table size ranges from 4x4 feet to 8x24 feet, making it essential to align your requirements with the available workspace in your manufacturing setup. Additionally, the material handling capabilities, such as a built-in water table for fume and debris management, can significantly enhance operational efficiency and improve finishing quality.

Moreover, the level of automation and control systems plays a pivotal role in user experience. Modern CNC plasma tables often feature advanced software that allows users to upload designs directly and manipulate settings on-the-fly. Optimal machines also integrate ergonomic designs for better user interface, essential for reducing operational fatigue and increasing productivity. As per a recent industry report, the demand for automated plasma cutting solutions is projected to grow by 7% annually, emphasizing the need to invest in technologically advanced machinery that can keep pace with evolving industry standards. Understanding these specifications ensures global buyers find a plasma table that perfectly suits their needs in the competitive landscape of manufacturing.

Comparing Popular CNC Plasma Table Brands Available in Canada

When searching for the perfect CNC plasma table in Canada, it's crucial to compare the popular brands that dominate the market. Each brand has its unique features, specifications, and pricing that can significantly impact your decision. Leading manufacturers such as Hypertherm, Miller Electric, and Lincoln Electric offer machines with different capabilities tailored to varying needs, from hobbyists to industrial applications.

Hypertherm is renowned for its advanced plasma cutting technology. Its models often include features like intuitive software, high-speed cutting capabilities, and exceptional precision. These machines are ideal for businesses looking to enhance productivity without compromising quality. On the other hand, Miller Electric is celebrated for its robust construction and reliability, making it a favorite among users who prioritize durability. The versatility of their CNC plasma tables makes them suitable for a wide range of materials and cutting conditions.

Lincoln Electric focuses on delivering cost-effective solutions without sacrificing performance. Their CNC plasma tables are designed for users who are budget-conscious yet require reliable technology. With various models available that offer ease of use and maintenance, Lincoln Electric machines cater well to both beginners and seasoned professionals. As buyers navigate through these options, understanding the specific capabilities of each brand will help them select the ideal CNC plasma table that aligns with their operational needs and budget constraints.

Budgeting for Your CNC Plasma Table: Costs and Financing Options

When budgeting for a CNC plasma table, potential buyers must navigate a complex landscape of costs, financing options, and additional expenses. According to a recent report published by MarketsandMarkets, the CNC plasma cutting machine market is projected to reach $4.81 billion by 2026, growing at a CAGR of 5.5%. This robust growth is partly due to increasing automation in manufacturing processes, suggesting that investing in a CNC plasma table can yield significant returns for businesses in the long run.

The initial investment in a CNC plasma table typically ranges from $20,000 to over $100,000, depending on specifications and capabilities, such as table size, precision, and automation features. Beyond the purchase price, buyers must also factor in maintenance costs, which can account for 10-15% of the equipment’s cost annually. Financing options are crucial, especially given that many buyers are opt for financing plans to ease cash flow constraints. Various manufacturers and financial institutions offer lease-to-own programs, which can be particularly beneficial for small to medium-sized enterprises (SMEs) aiming to maintain operational flexibility.

Moreover, regional factors play a significant role in budgeting. Canadian buyers may find it advantageous to explore government grants or incentives that support advanced manufacturing technologies. The Canadian government has been known to offer funding programs specifically aimed at improving competitiveness in the manufacturing sector. By carefully assessing equipment costs, financing options, and potential savings from local incentives, buyers can make informed decisions that align with their business goals while tapping into the growing CNC plasma equipment market.

Navigating the Canadian Market: Tips for Importing CNC Plasma Machines

When navigating the Canadian market for importing CNC plasma machines, understanding the specifications and market trends is crucial for global buyers. The Canadian CNC market is witnessing a notable growth trajectory, driven by increasing demand across various industries such as manufacturing, automotive, and metal fabrication. According to reports, the market is expected to expand significantly by 2033, with a compound annual growth rate (CAGR) of approximately 5.7% from 2023 to 2033. This growth indicates a promising landscape for businesses looking to invest in advanced machinery.

Moreover, as prospective buyers assess their options, it's important to consider the evolving regulatory environment in Canada. Recent updates from securities regulators that aim to simplify the initial public offering process reflect a broader trend of enhancing business opportunities within the country. For companies looking to import CNC plasma machines, these regulatory improvements may lead to a more favorable investment climate, boosting confidence in the acquisition of new technologies.

Competition is also intensifying, as various manufacturers focus on exporting their products to North America, including the Canadian market. This opens avenues for buyers to explore a wider selection of machinery, each optimized for specific applications. With careful research and consideration of local regulations, global buyers can better position themselves to make informed decisions when selecting their ideal CNC plasma machines in Canada.

English

English  Français

Français