Exploring the Features and Applications of the Best Industrial Plasma Table for Global Buyers

In the rapidly evolving landscape of industrial manufacturing, the demand for precision cutting and efficiency has led to the increasing adoption of Industrial Plasma Tables. According to a recent industry report by Grand View Research, the global plasma cutting equipment market is expected to reach $7.39 billion by 2025, growing at a CAGR of 5.5%. This growth is driven by the rising need for advanced metal fabrication technologies across various sectors, including automotive and aerospace.

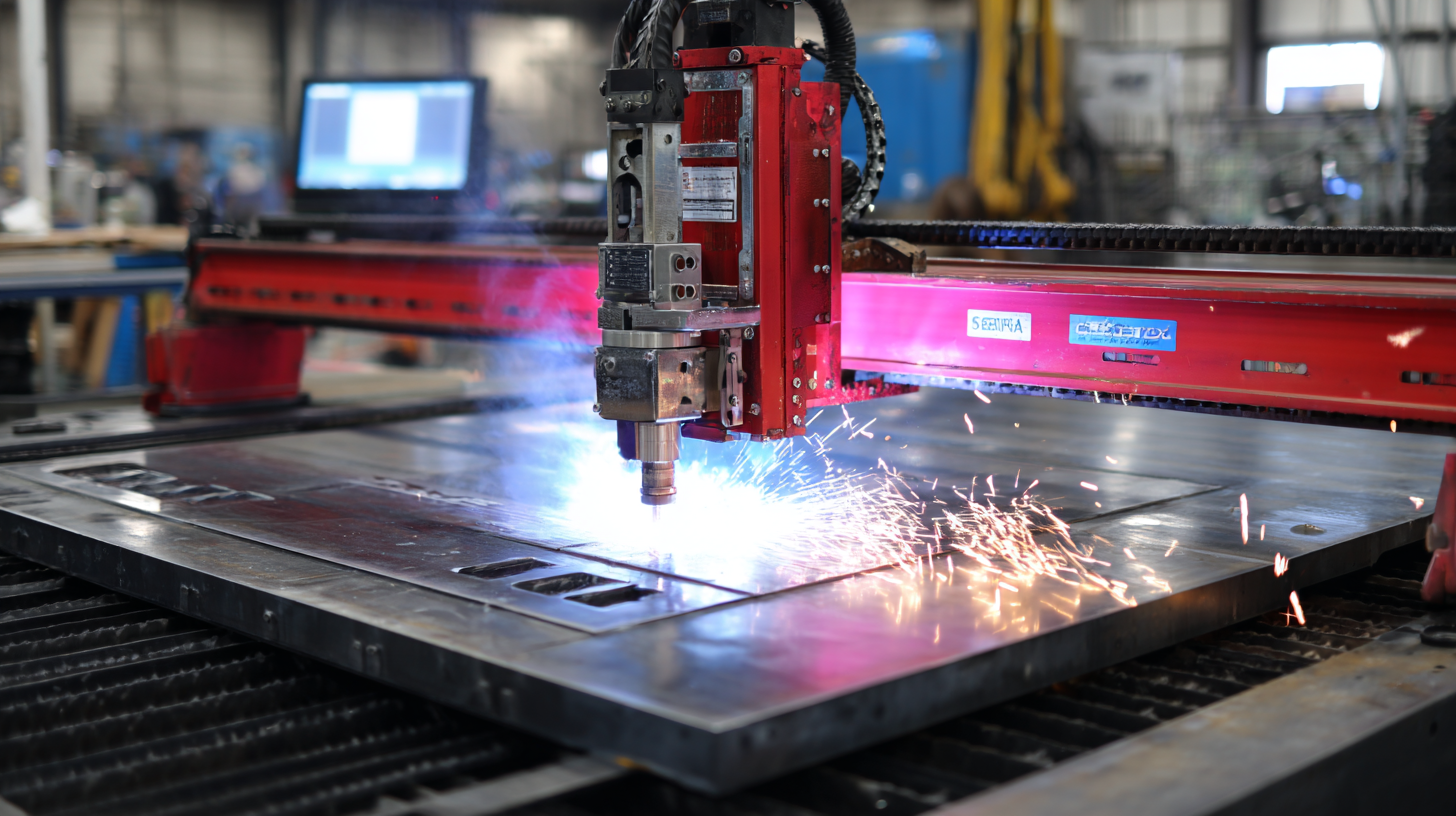

Industrial Plasma Tables are at the forefront of this evolution, enabling manufacturers to achieve intricate designs and superior finishes with unparalleled speed and accuracy. As global buyers seek to enhance their production capabilities, understanding the features and applications of the best Industrial Plasma Tables becomes crucial for staying competitive in today's market. This blog will delve into the essential characteristics of these cutting-edge tools and their practical applications across industries.

Benefits of Using Industrial Plasma Tables in Modern Manufacturing Processes

Industrial plasma tables have emerged as indispensable tools in modern manufacturing processes, primarily due to their ability to enhance precision and efficiency. These advanced machines utilize high-temperature plasma to cut through various materials rapidly, reducing manufacturing time and costs. As industries continually seek innovative solutions, the benefits of using industrial plasma tables are becoming increasingly evident. They not only improve cutting accuracy but also minimize waste, making them a sustainable choice in manufacturing.

Tip: When selecting the best industrial plasma table, consider features such as automated height sensing and built-in dust collection systems. These enhancements not only improve the cutting process but also contribute to a cleaner work environment by reducing airborne particles generated during cutting operations.

The integration of atmospheric plasma technology is also paving the way for new applications, such as decentralized ammonia production through plasma-activated processes. These advancements indicate a trend toward increased efficiency and sustainability in manufacturing, aligning with the ever-growing emphasis on environmental responsibility in industrial practices.

Tip: Staying updated with the latest technological advancements can significantly boost your company's competitiveness. Regularly attend industry conferences and workshops to learn about emerging trends and best practices in advanced manufacturing technologies.

Key Features to Consider When Choosing the Best Plasma Table for Your Needs

When selecting the best industrial plasma table for your operations, several key features should take precedence. First and foremost, the cutting speed and precision are critical, as they directly impact productivity and material usage. According to a market report from Research and Markets, high-end plasma tables can achieve cutting speeds up to 150 inches per minute while maintaining a precision tolerance of ±0.01 inches. This level of performance not only enhances efficiency but also reduces scrap costs, making it a vital consideration for manufacturers seeking to optimize their processes.

Another significant factor to evaluate is the table's software compatibility and control systems. The ability to integrate with advanced CAD/CAM software systems can streamline operations and aid in the design of complex parts. A report from Allied Market Research indicates that the global CAD software market is projected to reach $12 billion by 2026, emphasizing the growing trend toward computerized design and fabrication processes. Buyers should ensure that their selected plasma table supports such technological advancements to remain competitive in an evolving market landscape.

Emerging Technologies Shaping the Future of Industrial Plasma Cutting

The realm of industrial plasma cutting is rapidly evolving due to emerging technologies that promise to enhance efficiency, precision, and automation in manufacturing processes. According to a market research report by Mordor Intelligence, the global plasma cutting equipment market is projected to grow at a CAGR of 6.2% from 2021 to 2026, driven by increased demand across various industries such as automotive, aerospace, and construction. Innovations such as advanced control systems and AI-driven software are not only improving cut quality but also optimizing cutting paths, significantly reducing material waste.

Tip: When selecting a plasma table, consider investing in models that feature integrated AI capabilities. This technology analyzes cutting processes in real-time and adjusts parameters to ensure optimal performance, minimizing downtime and maximizing output.

Additionally, advancements in plasma technology itself are leading to more efficient power supplies and improved nozzle designs, allowing for cleaner cuts at higher speeds. The integration of smart technologies in these systems is reshaping how companies approach cutting tasks, indicating a shift towards fully automated workflows. A report by MarketsandMarkets forecasts that the automation of industrial plasma cutting processes will reach a market size of approximately $5 billion by 2025, underscoring the trend towards efficiency.

Tip: Always evaluate the after-sales support and software updates provided by plasma table manufacturers. A reliable support system is crucial for troubleshooting and maintaining the advanced features of your cutting equipment, ensuring sustained efficiency over time.

Market Trends and Growth Potential of Plasma Tables by 2025

The plasma cutting machine market is witnessing significant growth, fueled by innovative technological advancements and an increasing demand for precision cutting in various industries. As of 2024, the global CNC plasma cutting machines market was valued at approximately USD 673.2 million and is expected to soar to USD 1.1 billion by 2034, demonstrating a robust compound annual growth rate (CAGR) of over 5.8%. This trend is primarily driven by the efficiency and accuracy that CNC plasma cutters offer compared to manual methods, making them highly attractive for industrial applications.

Additionally, the plasma welding machines segment is also poised for expansion. Recent insights indicate a shift in market dynamics, where companies are increasingly investing in automated welding solutions. By 2025, the growth opportunities in this sector will be significant, supported by the rising demand for high-performance welding techniques across manufacturing sectors. The advanced functionalities of plasma welding machines cater to a broad range of applications, reinforcing the projected growth trajectory in this market. This surge in both plasma cutting and welding technologies highlights a promising future for global buyers looking to enhance their operational capabilities.

Exploring the Features and Applications of the Best Industrial Plasma Table for Global Buyers - Market Trends and Growth Potential of Plasma Tables by 2025

| Dimension | Feature | Application | Market Trend (2025) | Growth Potential (%) |

|---|---|---|---|---|

| 4x8 ft | High Precision Cutting | Metal Fabrication | Increased Demand | 8% |

| 5x10 ft | Automatic Height Adjustment | Automotive Parts | Technological Advancements | 10% |

| 6x12 ft | Dynamic Cutting System | Aerospace Components | Rising Industrial Usage | 12% |

| 3x6 ft | Compact Design | Art and Sign Making | Emerging Markets | 15% |

Applications of Plasma Cutting Across Various Industries and Their Impact

Plasma cutting technology is revolutionizing various industrial sectors by offering precise and efficient solutions for material processing. The versatility of plasma cutting finds applications in shipbuilding, aerospace, automotive manufacturing, and even food processing.

For instance, cold plasma technology is increasingly recognized for its ability to inactivate microorganisms while maintaining food quality, positioning it as a sustainable option in food safety practices. Reports indicate that the cold plasma market is anticipated to significantly grow, driven by rising consumer demand for safer food processing methods.

Tip: When selecting a plasma cutting solution, consider the specific industry requirements, as well as the efficiency and accuracy of different plasma technologies. The choice between low pressure/vacuum plasma and atmospheric plasma can dramatically impact production quality and cost-effectiveness.

As countries like China advance in their innovation capabilities, the industrial landscape is rapidly evolving. Emerging trends indicate that the Metal Processing Machine Industry is projected to rise from USD 94.52 billion in 2023 to USD 120.0 billion by 2032. This boom reflects the increasing investment in advanced manufacturing technologies, including plasma cutting systems, which are essential for driving productivity and competitiveness in global markets.

Tip: Keeping abreast of industry trends and technological advancements can significantly influence operational efficiency and business growth. Engaging with ongoing research and development in plasma technologies can provide a strategic edge in a highly competitive environment.

English

English  Français

Français