Envisioning the Future of Compact CNC Plasma Cutting Technology for Global Buyers

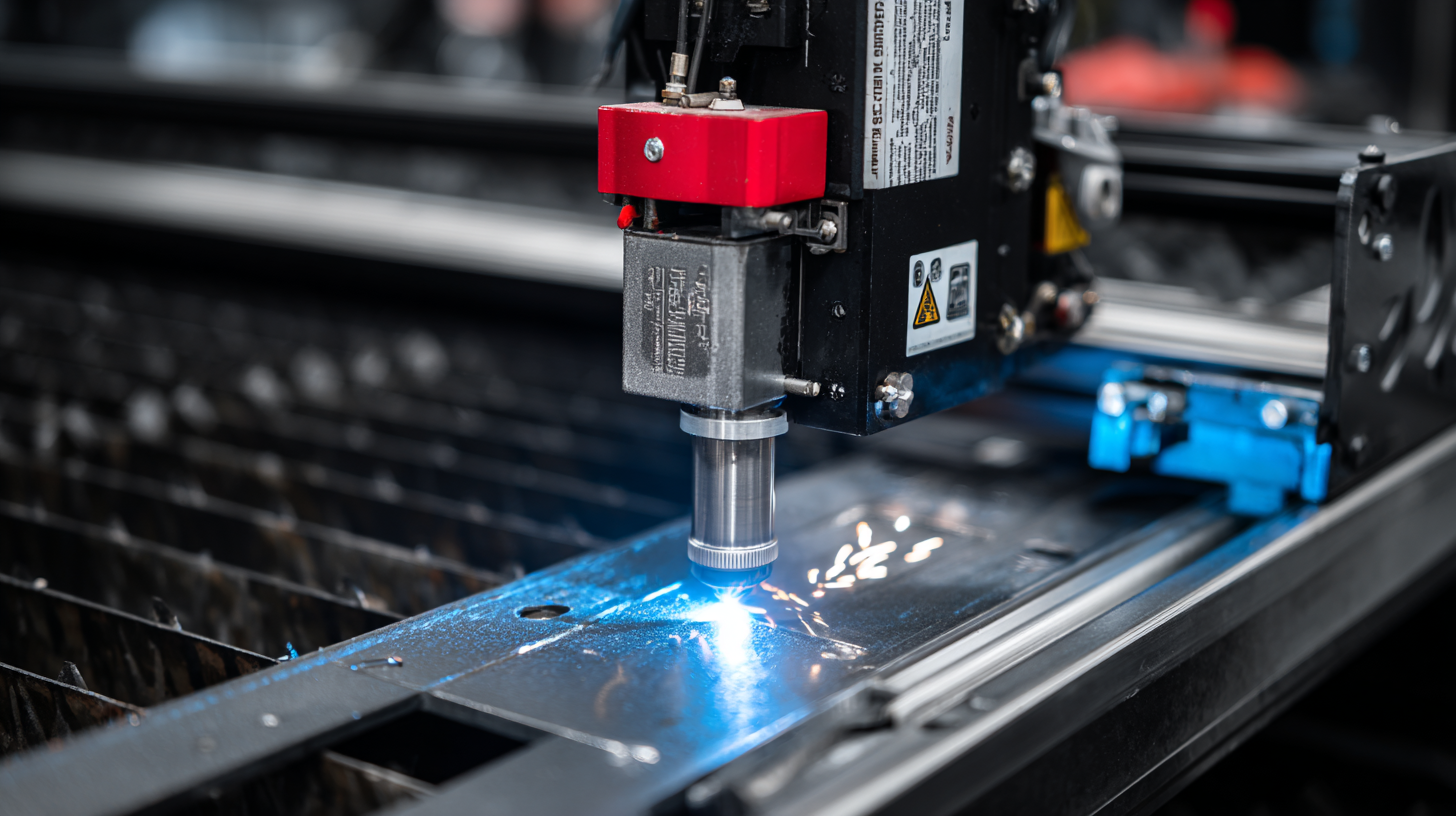

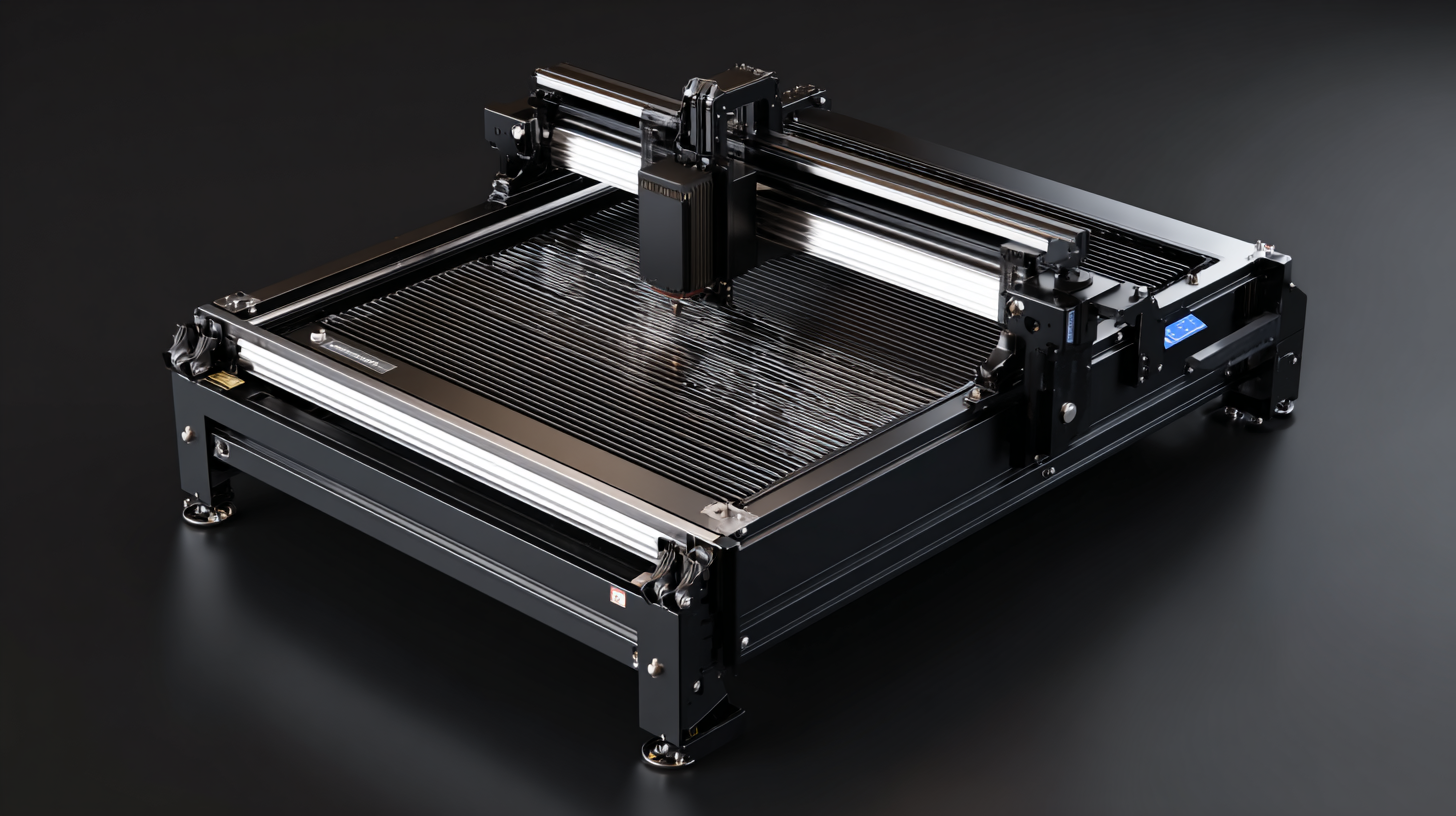

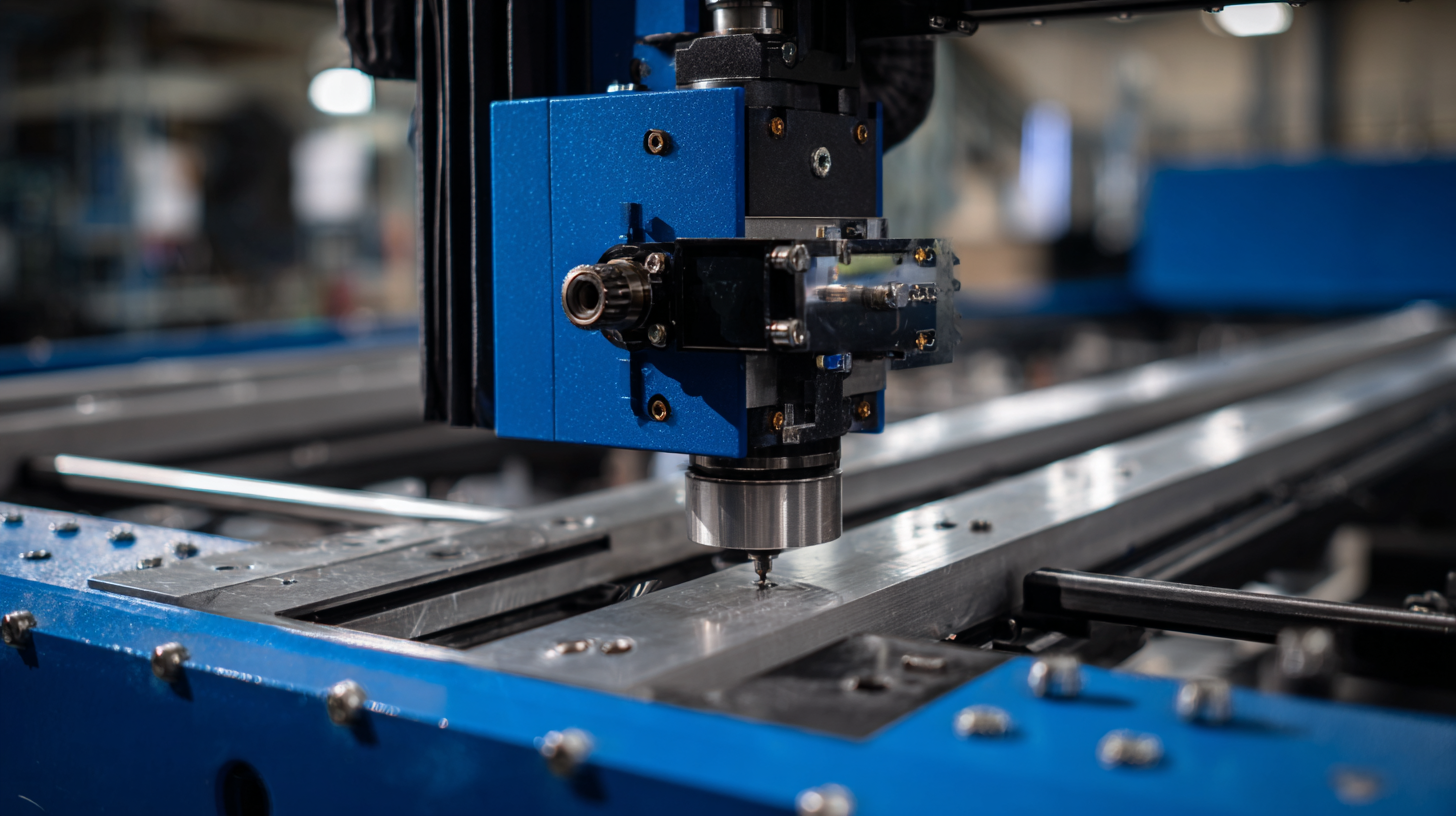

In the rapidly evolving landscape of manufacturing technology, the demand for precision cutting solutions has spurred innovations, particularly in the realm of compact machinery. Enter the Small CNC Plasma Cutter, a game-changer for businesses seeking high-quality, efficient cutting capabilities without the bulk of traditional models. As global buyers increasingly prioritize versatility and space-saving design, this advanced technology stands at the forefront, enabling manufacturers to optimize their workflows and improve productivity.

In envisioning the future of compact CNC plasma cutting technology, we must explore how these tools not only enhance operational efficiency but also cater to the diverse needs of industries worldwide. Furthermore, as leading manufacturing factories aim to export globally, understanding the impact and advantages of the Small CNC Plasma Cutter will be crucial in maintaining a competitive edge and meeting the demands of an ever-changing market landscape.

The Importance of Import and Export Certifications in CNC Plasma Cutting Industry

In the rapidly evolving landscape of the CNC plasma cutting industry, import and export certifications play a crucial role, especially for global buyers. The increasing demand for precision and efficiency in manufacturing processes has driven many companies to seek certified technologies that guarantee quality and compliance with international standards. According to recent market analysis, the global CNC plasma cutting machine market was valued at approximately $1.5 billion in 2022 and is expected to grow significantly by 2028. This trend highlights the importance of adhering to regulatory requirements, which not only facilitates smoother transactions but also enhances consumer confidence in the products being offered.

As companies look to capitalize on this growing market, the need for stringent import and export certifications becomes evident. These certifications ensure that the machinery meets safety, environmental, and performance standards, thereby allowing manufacturers to gain access to competitive markets, such as the US. For instance, the recent news of a company successfully exporting semi-trailers to the US emphasizes the need for certified products in addressing market demands. In addition, as manufacturers invest in technology for enhanced productivity, the unyielding focus on certified CNC plasma cutting tools can further optimize their operations and strengthen their foothold in global trade.

Envisioning the Future of Compact CNC Plasma Cutting Technology for Global Buyers

This bar chart illustrates the projected growth of the global CNC plasma cutting market over a period from 2020 to 2024. The increasing demand for compact CNC plasma cutting technology emphasizes the importance of import and export certifications in ensuring product quality and compliance within the industry.

Navigating Regulatory Requirements for Global Buyers of CNC Plasma Cutters

Navigating the complex landscape of regulatory requirements is essential for global buyers of CNC plasma cutters. The rise of this technology has been accompanied by increasing scrutiny from regulatory bodies, ensuring that machines comply with safety, environmental, and performance standards. According to a recent report by Research and Markets, the global CNC plasma cutting machine market is projected to reach USD 6.2 billion by 2025, highlighting the significance of establishing uniform regulations across different regions to facilitate international trade.

For buyers, understanding the specific regulations set by organizations such as ISO and OSHA can be a crucial first step. Different countries may have varying requirements regarding emissions, noise levels, and operational safety features. Buyers should prioritize suppliers who not only meet these standards but also provide comprehensive documentation that can expedite the compliance process.

Tip: Always request certification details from manufacturers, as this can save time and ensure that your investment aligns with your local regulations. Furthermore, engaging with industry-specific consultants can provide insights into emerging regulatory trends, helping buyers stay ahead of the curve. Encrypting compliance measures into supplier agreements can also safeguard your purchase against future regulatory shifts.

How Certifications Influence Quality Assurance in Plasma Cutting Technology

In the rapidly evolving field of compact CNC plasma cutting technology, the role of certifications in ensuring quality assurance cannot be overstated. According to a recent report by MarketsandMarkets, the plasma cutting market is projected to grow from $4.2 billion in 2020 to $5.5 billion by 2025, driven largely by increasing demand for precision cutting in diverse industries. As buyers worldwide seek reliable and efficient solutions, certifications such as ISO 9001 and CE marking have emerged as benchmarks for quality, enabling manufacturers to distinguish their products in a competitive market.

In the rapidly evolving field of compact CNC plasma cutting technology, the role of certifications in ensuring quality assurance cannot be overstated. According to a recent report by MarketsandMarkets, the plasma cutting market is projected to grow from $4.2 billion in 2020 to $5.5 billion by 2025, driven largely by increasing demand for precision cutting in diverse industries. As buyers worldwide seek reliable and efficient solutions, certifications such as ISO 9001 and CE marking have emerged as benchmarks for quality, enabling manufacturers to distinguish their products in a competitive market.

Furthermore, research from the Fabricators & Manufacturers Association indicates that companies adhering to strict certification standards report a 30% reduction in operational errors. This highlights the direct correlation between certification and product reliability, instilling confidence in global buyers. Seminars and workshops by organizations like the American Welding Society emphasize the importance of adhering to these quality standards, advocating for a uniform compliance framework across manufacturers. As the global market for plasma cutting technology expands, the influence of certifications will be crucial in shaping the future landscape and ensuring that buyers receive the best possible equipment for their needs.

The Impact of Trade Policies on Compact CNC Plasma Cutting Equipment Market

The compact CNC plasma cutting technology market is experiencing significant shifts due to evolving trade policies worldwide. As countries adapt their regulations regarding imports and exports, manufacturers of this innovative equipment must stay agile. Export duties, tariffs, and trade agreements can dramatically influence the pricing and availability of cutting-edge plasma cutting machines. This dynamic landscape presents both challenges and opportunities for buyers looking to invest in this essential technology.

Tip: Research the specific trade regulations in your region to understand how tariffs might affect the overall cost of compact CNC plasma cutting equipment. Staying informed will help you make a more cost-effective decision.

Moreover, the current global push towards sustainability is reshaping market demand. Buyers are increasingly inclined towards equipment that not only offers precision cutting but also minimizes waste and energy consumption. Trade policies promoting environmentally-friendly technologies can give preference to manufacturers who adhere to eco-conscious practices, driving innovation and competitiveness in the compact CNC plasma cutting sector.

Tip: Look for suppliers who are compliant with the latest environmental standards, as their products may qualify for favorable trade terms and incentives, ultimately benefiting your bottom line.

Future Trends in Certification Standards for CNC Plasma Cutting Technology

As the global demand for precision metal fabrication continues to rise, the certification standards for CNC plasma cutting technology are evolving to meet both regulatory requirements and customer expectations. A key trend in this evolution is the emphasis on quality assurance throughout the manufacturing process. Certifications are becoming more rigorous, focusing on aspects such as energy efficiency, safety protocols, and the durability of the machines. By adhering to these elevated standards, manufacturers can ensure that their equipment not only performs optimally but also aligns with international regulations, making them more appealing to global buyers.

Another notable trend is the increasing recognition of environmental sustainability in certification processes. As industries worldwide strive to reduce their carbon footprints, plasma cutting technology is being scrutinized for its eco-friendliness. Future certification standards are likely to incorporate metrics that evaluate the energy consumption of CNC plasma cutting units and the waste management practices employed during operation. This shift will encourage manufacturers to innovate more sustainable solutions, reinforcing their commitment to environmental stewardship while also opening new markets that prioritize green technologies.

English

English  Français

Français