Innovative Approaches for Best Small Plasma Table in 2025 Industry Technology Trends

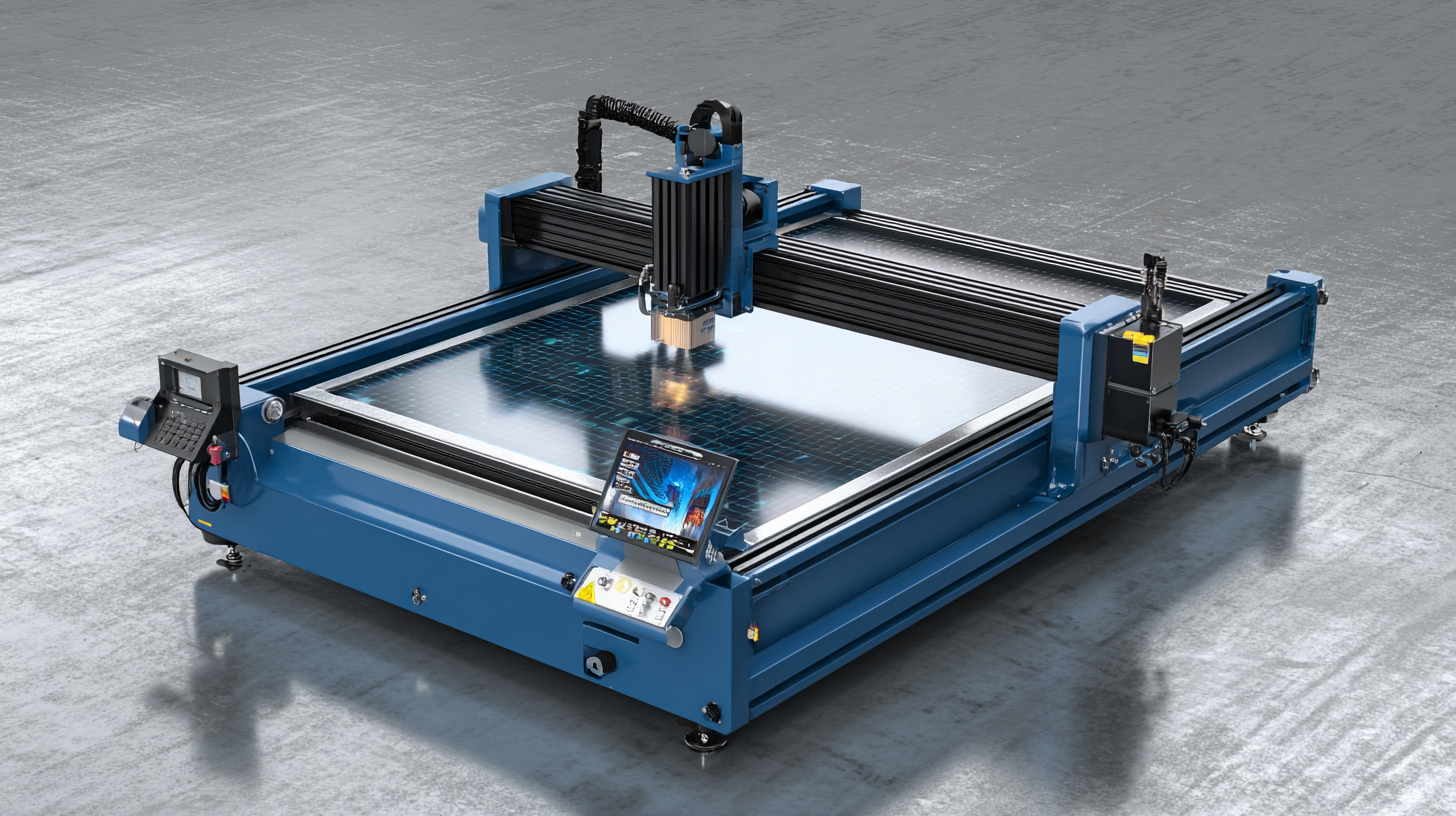

The landscape of industrial manufacturing is evolving rapidly, with cutting-edge technology playing a crucial role in shaping the future. Among these advancements, the Small Plasma Table has emerged as a significant tool, enabling precision cutting and enhancing productivity across various sectors. According to a recent market analysis by Allied Market Research, the global plasma cutting equipment market is projected to reach $7.3 billion by 2025, driven by the increasing demand for efficient, high-quality manufacturing processes. As industries seek to optimize their operations, adopting innovative strategies for integrating Small Plasma Tables is essential. This blog explores the top strategies for leveraging this technology, emphasizing the trends that are set to define the industry in 2025 and beyond, ensuring businesses stay competitive in a dynamic marketplace.

Innovative Features to Look for in Small Plasma Tables for 2025

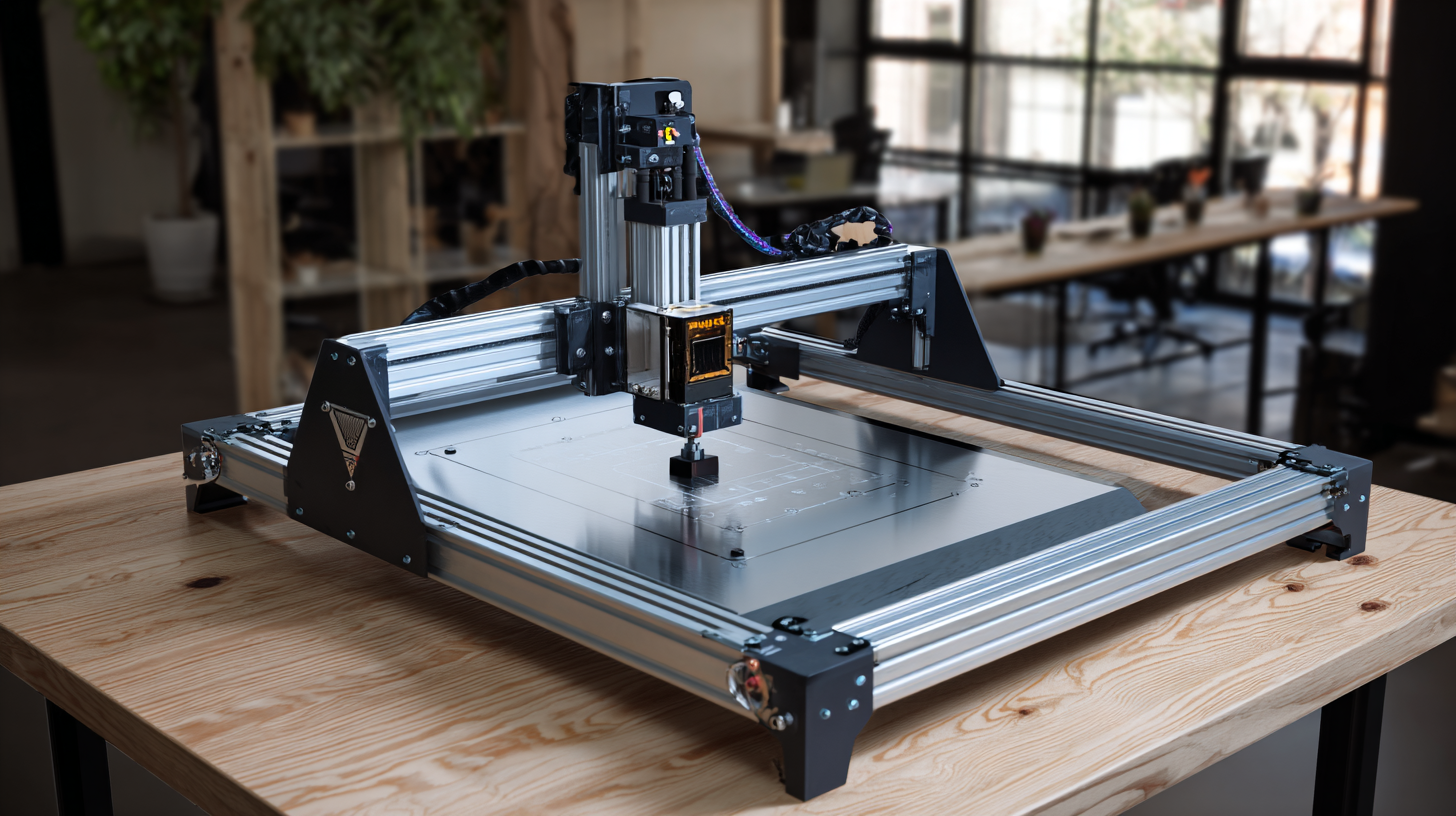

As we approach 2025, the small plasma table industry is evolving rapidly, incorporating advanced technologies that enhance efficiency and usability. A critical feature to consider is the integration of AI-driven software, enabling users to optimize their cutting paths and reduce waste. According to a recent report by IBISWorld, the adoption of automation in the fabrication industry is projected to boost productivity by 30% over the next five years, making plasma tables equipped with smart technology a valuable investment for both small businesses and larger manufacturers.

Another innovative feature gaining traction is the inclusion of modular designs, which allow for easy upgrades and modifications. This flexibility is crucial as industries adapt to changing demands. A survey by MarketsandMarkets indicates that 54% of manufacturers are prioritizing scalability in their equipment to maintain a competitive edge. Furthermore, advancements in plasma cutting technology, such as improved plasma arcs and consumables that last longer, are expected to enhance the precision of small plasma tables, thereby reducing operational costs and increasing overall output. As 2025 approaches, these features will redefine the landscape of small plasma tables, catering to the evolving needs of manufacturers across various sectors.

Innovative Approaches for Best Small Plasma Table in 2025 Industry Technology Trends

| Feature | Description | Benefits | Expected Impact in 2025 |

|---|---|---|---|

| Advanced Plasma Technology | Utilizes high-quality plasma for cleaner cuts and precision. | Improved cut quality and reduced waste material. | Increased efficiency in manufacturing processes. |

| Smart Connectivity | Integration with IoT for remote monitoring and control. | Enhances operational efficiency and machine management. | Real-time data analytics for better decision-making. |

| User-Friendly Interface | Intuitive touchscreen controls and software integration. | Simplifies operation and reduces training time. | Wider adoption across various skill levels in workforce. |

| Portability | Compact design for easy movement and transportation. | Flexibility to operate in different locations. | Increased utilization in small businesses and workshops. |

| Energy Efficiency | Mechanisms designed to minimize power consumption. | Lower energy bills and positive environmental impact. | Trend towards sustainable practices in manufacturing. |

Top Industry Leaders and Their Contributions to Plasma Technology

As plasma technology continues to evolve, industry leaders like Dr. Alexander Fridman are at the forefront of innovation. Recently honored for his groundbreaking contributions, Dr. Fridman’s work is pivotal in shaping the future of plasma applications across various sectors, from healthcare to energy. His influence reflects a broader trend within the industry, where luminaries are driving advancements that enhance the efficiency and capabilities of plasma systems.

In 2025, the landscape of plasma technology will be heavily influenced by these innovative leaders and their commitment to research and development. The global plasma technology market is projected to grow at a CAGR of 6.8%, reaching $8.4 billion by 2025. This growth highlights the increasing demand for small plasma tables, particularly in sectors requiring precision and compact solutions. Furthermore, initiatives across countries, including strides in AI integration with plasma technology, suggest that collaboration between academia and industry will prove crucial for sustaining this momentum. As market dynamics shift, the contributions of key figures will undoubtedly determine the evolution of plasma technology.

Sustainable Materials and Eco-Friendly Practices in Plasma Cutting

The landscape of plasma cutting technology is rapidly evolving, with a significant shift towards sustainable materials and eco-friendly practices. According to a report by MarketsandMarkets, the global plasma cutting market is expected to reach $6.22 billion by 2025, driven by increased demand for efficient and environmentally conscious production methods. This growth reflects a broader trend in the industry where manufacturers are emphasizing the use of recyclable materials and non-toxic cutting agents, minimizing the environmental footprint of their operations.

Additionally, the integration of advanced technologies into plasma cutting processes is enhancing sustainability. For instance, the adoption of high-precision plasma cutters capable of reducing waste by up to 30% is transforming traditional practices. A study from the American Welding Society highlights that using optimized cutting paths and reducing kerf width can significantly decrease material wastage. By prioritizing sustainable practices, companies not only comply with regulatory standards but also appeal to the growing base of environmentally conscious consumers. This focus underscores a commitment to innovation while ensuring that the plasma cutting industry can thrive sustainably in the years ahead.

The Role of Automation and AI in Enhancing Plasma Cutting Efficiency

As the plasma cutting industry embraces the future, the integration of automation and artificial intelligence (AI) is set to revolutionize efficiency and precision in manufacturing processes. In 2023, a report from MarketsandMarkets projected that the global plasma cutting equipment market would reach $4.78 billion by 2026, growing at a CAGR of 5.2%. This growth is largely fueled by advancements in technology that streamline operations, reduce material waste, and enhance output quality.

Automated plasma cutting systems powered by AI are at the forefront of this transformation. These systems utilize machine learning algorithms to optimize cutting paths and minimize cycle times, significantly boosting throughput. A study conducted by Deloitte found that businesses employing automated solutions in their production lines reported a 30% increase in overall efficiency. Additionally, AI-driven analytics provide actionable insights into equipment performance, helping operators preemptively address maintenance issues and reduce downtime. Such innovations not only enhance productivity but also promote a safer working environment by minimizing human intervention in hazardous tasks.

With the advent of smart plasma tables, companies can expect to see more streamlined operations and cost reductions. As the industry shifts towards these innovative technologies, manufacturers that invest in automation and AI will be better positioned to compete and thrive in the evolving landscape of plasma cutting.

Comparative Analysis: Best Small Plasma Tables in 2025 for Different Industries

As industries continue to evolve in 2025, small plasma tables are becoming increasingly vital across various sectors, including automotive, aerospace, and metal fabrication. The demand for precision and efficiency drives the adoption of advanced CNC plasma cutting technologies. According to the CNC Plasma Cutting Machines Market Size report, the global market was valued at USD 673.2 million in 2024, with an anticipated growth rate of over 5.1% from 2025 to 2034. This growth reflects the rising need for versatile and high-performance equipment that meets the specific requirements of distinct industries.

Different sectors are tailoring their needs to optimize productivity and enhance output quality. For example, in the automotive industry, small plasma tables are being leveraged for intricate component fabrication, allowing manufacturers to streamline their processes while maintaining high standards of accuracy. In contrast, metal fabrication shops are utilizing these tables for rapid prototyping and custom design work, which is crucial in meeting market demands swiftly. This comparative analysis of the best small plasma tables in 2025 will highlight not only their technological advancements but also how they are being adapted to cater to the unique demands of diverse industries.

English

English  Français

Français