9 Key Benefits of Using a Cnc Cutting Table in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, the integration of advanced technologies is crucial for maintaining competitive advantage. One such innovation that has gained prominence is the CNC cutting table, a versatile tool that not only enhances precision in fabrication but also improves overall production efficiency. According to a recent industry report by Grand View Research, the global market for CNC machines is expected to reach $100 billion by 2025, highlighting the growing reliance on automated solutions in manufacturing processes. The adoption of CNC cutting tables can lead to significant cost savings, reduced waste, and increased output, making them indispensable in various industries including aerospace, automotive, and metalworking. As manufacturers strive to optimize their operations, understanding the nine key benefits of using a CNC cutting table is essential for leveraging this technology to its full potential.

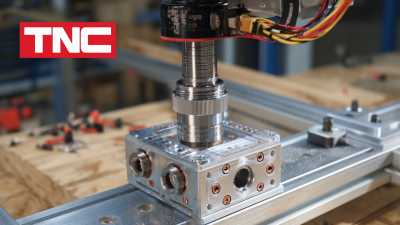

Enhancing Precision: How CNC Cutting Tables Outperform Traditional Methods

CNC cutting tables have revolutionized modern manufacturing by significantly enhancing precision compared to traditional cutting methods. According to a report by MarketsandMarkets, the global CNC machine market is expected to grow to $117.50 billion by 2025, driven by the increasing demand for accuracy and efficiency in production processes. Unlike manual cutting techniques, which can result in variances due to human error, CNC technology guarantees repeatable precision, with tolerances often within ±0.001 inches. This level of accuracy is crucial for industries such as aerospace and automotive, where even the slightest deviation can compromise safety and performance.

Moreover, CNC cutting tables streamline production processes by reducing setup times and material waste. Industry research indicates that using CNC technology can decrease cutting time by up to 30%, enabling manufacturers to optimize their operations and respond quickly to market demands. By minimizing scrap rates—often as low as 1%—manufacturers not only save on material costs but also contribute to sustainability efforts. As companies increasingly prioritize operational efficiency and environmental responsibility, adopting CNC cutting tables offers a clear competitive advantage in the fast-evolving manufacturing landscape.

Increasing Production Efficiency Through Automated Cutting Solutions

In today's fast-paced manufacturing landscape, automation is the key to enhancing production efficiency, and a CNC cutting table stands at the forefront of this technological revolution. These machines enable precise cutting with minimal human intervention, significantly reducing error rates and production times. By automating the cutting process, manufacturers can focus on scaling their operations without being bogged down by repetitive manual tasks.

Tips: Ensure that your CNC cutting table is equipped with the latest software and tools tailored to your specific material needs. Regularly update your maintenance schedule to keep the machine performing optimally and to prevent costly downtime.

Moreover, integrating CNC cutting tables allows for the seamless execution of complex designs, fostering innovation in product development. The ability to easily adjust designs or switch from one project to another means that manufacturers can respond swiftly to market demands.

Tips: Train your team on the latest CNC technologies and design software to maximize the potential of your cutting table. Establish a workflow that facilitates quick reconfiguration of project setups to enhance production agility. By leveraging these automated solutions, manufacturing operations can achieve higher productivity levels and meet today’s competitive standards.

Cost-Effectiveness: Long-Term Savings with CNC Cutting Technology

In the contemporary manufacturing landscape, cost-effectiveness is more crucial than ever, and CNC cutting technology stands out as a significant contributor to long-term savings. CNC cutting tables offer precision and efficiency that traditional methods cannot match, reducing waste and minimizing the need for material rework. With the rise of automation in manufacturing processes, implementing CNC machines results in streamlined operations, enhanced productivity, and lower labor costs. This not only translates to immediate financial benefits but also fosters sustainable practices by conserving resources.

Moreover, advancements such as AI integration are shaping the future of CNC machining, enhancing the ability to predict and mitigate costs further. The ability to create digital twins of manufacturing processes allows companies to optimize workflows and control expenses effectively, ensuring that production runs smoothly and efficiently. As industries embrace these innovative technologies, the long-term savings associated with CNC cutting technology become increasingly apparent, positioning it as a cornerstone of modern manufacturing strategies.

Cost-Effectiveness of CNC Cutting Technology

This chart illustrates the cost factors involved in using CNC cutting technology in modern manufacturing. It highlights the initial investment, ongoing labor costs, material waste, production speed benefits, and estimated long-term savings, showcasing the financial advantages CNC cutting can offer.

Versatility of Materials: A Look at CNC Cutting Table Applications

CNC cutting tables have revolutionized modern manufacturing by offering unparalleled versatility across a wide range of materials. From metals and plastics to textiles and wood, these advanced machines can seamlessly adapt to cut, engrave, or shape diverse substances with high precision. This flexibility allows manufacturers to tackle various projects, catering to both small bespoke orders and large-scale production runs efficiently.

One of the most significant advantages of CNC cutting tables is their ability to facilitate intricate designs that would be labor-intensive with traditional cutting methods. As technology continues to evolve, new applications are emerging, particularly in fields like automotive design, aerospace components, and even biomedical engineering. The integration of various cutting technologies, such as plasma and laser cutting, further enhances the capabilities of CNC cutting tables, enabling manufacturers to push the boundaries of innovation while maintaining efficiency and cost-effectiveness in their operations. Consequently, the adoption of CNC cutting technology is becoming increasingly essential for businesses aiming to stay competitive in the ever-evolving manufacturing landscape.

Improved Design Flexibility: Adapting to Custom Manufacturing Needs

In modern manufacturing, the ability to adapt designs swiftly to meet custom needs is crucial, and CNC cutting tables play a pivotal role in enhancing design flexibility. According to a report by MarketsandMarkets, the global CNC cutting machine market is projected to reach $8.5 billion by 2025, driven by the increasing demand for custom solutions across various industries. This technology allows manufacturers to create intricate designs with precision, minimizing material waste and facilitating rapid prototyping.

CNC cutting tables enable manufacturers to easily modify design parameters without incurring significant costs or time delays, making it easier to cater to unique customer requirements. A survey conducted by the Manufacturing Institute revealed that over 50% of manufacturing companies prioritize flexibility in their operations to respond to market changes swiftly. This responsiveness not only enhances customer satisfaction but also supports the development of innovative products that stand out in a competitive landscape. By leveraging CNC technology, manufacturers can stay ahead of the curve, embracing the ever-evolving demands of custom manufacturing.

9 Key Benefits of Using a CNC Cutting Table in Modern Manufacturing - Improved Design Flexibility: Adapting to Custom Manufacturing Needs

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| Increased Precision | CNC cutting tables provide precise cuts, reducing material waste and improving product quality. | Enhances overall production efficiency. |

| Enhanced Design Flexibility | Easily adapt designs to meet custom manufacturing requests. | Enables personalized products, satisfying specific customer needs. |

| Faster Production Times | Automated cutting speeds up production processes. | Increases manufacturing output and competitiveness. |

| Cost Efficiency | Reduces labor costs and minimizes material waste. | Improves profit margins for manufacturers. |

| Sustainability | Optimizes material usage, promoting environmentally friendly practices. | Aligns with global sustainability goals. |

| Versatility | Can cut various materials, including metal, wood, and plastics. | Allows manufacturers to diversify their product offerings. |

| Improved Safety | CNC technology minimizes manual handling of sharp tools. | Creates a safer work environment for employees. |

| Data-Driven Production | Collects data for analytics to optimize processes. | Facilitates continuous improvement in manufacturing operations. |

| Scalability | Easily scale production up or down based on market demand. | Enables businesses to respond quickly to market changes. |

Related Posts

-

Discover Unmatched Manufacturing Excellence with the Best CNC Cutting Table from World Class Chinese Factory

-

Unlocking Precision and Efficiency with Best Cnc Cutting Table Technical Specifications and Setup Guide

-

Maximizing Efficiency and Reducing Downtime with Cnc Plasma Cutter Maintenance Tips

-

Unlocking Precision and Efficiency with Custom Plasma Cutting Solutions

-

7 Reasons Why the Best CNC Plasma Table Revolutionizes Metal Fabrication Efficiency

-

7 Amazing Benefits of Cnc Cutting Tables That Transform Your Manufacturing Process

English

English  Français

Français