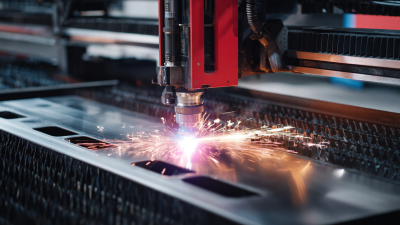

How to Optimize Your Plasma Cutting Machine for Maximum Efficiency and Precision

In the competitive landscape of metal fabrication, optimizing a Plasma Cutting Machine is essential for enhancing operational efficiency and ensuring precision in cutting processes. According to industry reports, companies that effectively calibrate and maintain their plasma cutting equipment can experience up to a 30% reduction in operational costs and a significant increase in productivity.

Advanced plasma cutting technologies not only enable clean and precise cuts but can also reduce material waste by as much as 15%, contributing to both economic and environmental sustainability. As manufacturers look to improve their bottom lines and output quality, understanding the intricacies of plasma cutting optimization becomes crucial.

This guide aims to provide insights and strategies that will help operators maximize the potential of their Plasma Cutting Machines, ensuring they remain competitive in an ever-evolving market.

Advanced plasma cutting technologies not only enable clean and precise cuts but can also reduce material waste by as much as 15%, contributing to both economic and environmental sustainability. As manufacturers look to improve their bottom lines and output quality, understanding the intricacies of plasma cutting optimization becomes crucial.

This guide aims to provide insights and strategies that will help operators maximize the potential of their Plasma Cutting Machines, ensuring they remain competitive in an ever-evolving market.

Understanding the Components of a Plasma Cutting Machine for Efficient Operation

Understanding the components of a plasma cutting machine is essential for achieving efficient operation and maximizing performance. At the heart of the system is the power supply, which generates the high voltage necessary to create an arc between the electrode and the workpiece. This arc transforms the gas into plasma, allowing for precise cutting of various materials. Regular maintenance of the power supply, including checking connections and replacing worn components, is crucial to ensure sustained efficiency.

Understanding the components of a plasma cutting machine is essential for achieving efficient operation and maximizing performance. At the heart of the system is the power supply, which generates the high voltage necessary to create an arc between the electrode and the workpiece. This arc transforms the gas into plasma, allowing for precise cutting of various materials. Regular maintenance of the power supply, including checking connections and replacing worn components, is crucial to ensure sustained efficiency.

Another critical component is the torch, which directs the plasma stream onto the material. Selecting the appropriate torch and nozzle size for the thickness and type of metal being cut can significantly impact cutting quality and speed. Additionally, the cooling system plays a vital role in preventing overheating during prolonged operation. Keeping the cooling lines clear and ensuring proper airflow will enhance the lifespan of the torch and maintain cutting precision. By understanding and maintaining these components, operators can optimize their plasma cutting machines for superior efficiency and more accurate results.

Calibrating Your Plasma Cutter: Essential Steps for Precision Cuts

Calibrating your plasma cutter is a crucial step in achieving precision cuts and ensuring maximum efficiency in your metalworking projects. The first step involves checking the air pressure. An optimal air pressure setting not only enhances cut quality but also prevents rough edges and excessive dross. Use a reliable gauge to adjust the pressure according to the specifications of your machine, ensuring consistent results across various materials and thicknesses.

Another essential calibration step is adjusting the cutting speed. Each plasma cutting machine has a recommended speed for the materials it processes. Performing test cuts can help you determine the ideal speed settings for your specific application. Additionally, make sure to align the nozzle correctly; a misaligned nozzle can lead to uneven cuts and increased wear on the consumables. Regularly inspecting and replacing worn components, such as electrodes and nozzles, will also contribute to maintaining precision and efficiency over time.

Selecting the Right Plasma Cutting Consumables for Optimal Performance

Selecting the right plasma cutting consumables is essential for achieving optimal performance in your plasma cutting machine. Various studies, including those from the American Welding Society, highlight that using specialized nozzles, electrodes, and shields can enhance cutting speed and precision by up to 30%. High-quality consumables are designed to ensure consistent arc stability and reduced downtime, which are critical factors for maximizing operational efficiency.

For example, according to a report published by the Fabricators & Manufacturers Association, integrating advanced consumables can help decrease kerf width, resulting in cleaner cuts and less material wastage. Furthermore, different applications may require specific types of consumables; using hypertherm or thermal dynamics components can provide superior results for thick materials versus thinner stock. Ensuring that your consumables are compatible with your plasma cutting machine also plays a crucial role in maintaining performance, as mismatched components can lead to inconsistent quality and increased costs.

How to Optimize Your Plasma Cutting Machine for Maximum Efficiency and Precision

| Parameter | Value | Optimal Range | Impact on Performance |

|---|---|---|---|

| Cutting Speed (ipm) | 30 | 20 - 40 | Higher speeds improve productivity but may affect cut quality. |

| Arc Voltage (V) | 100 | 90 - 110 | Proper voltage ensures stable arc and better cut quality. |

| Gas Flow Rate (CFH) | 60 | 50 - 70 | Correct gas flow prevents dross and enhances cut edge quality. |

| Nozzle Diameter (mm) | 1.0 | 0.8 - 1.2 | Choosing the right nozzle affects cut width and quality. |

| Material Thickness (mm) | 10 | 1 - 20 | Thickness affects cutting time and required settings. |

Implementing Best Practices for Maintenance and Care of Plasma Cutting Equipment

Proper maintenance and care of your plasma cutting equipment are essential for ensuring optimal performance and longevity. Regular inspections and cleaning are vital to prevent the buildup of slag and contaminants that can affect cutting quality. Make it a habit to check the torch and consumables for wear and tear, replacing them as necessary. This not only enhances precision but also minimizes downtime, allowing for seamless workflow in your operations.

**Tip:** Always use high-quality consumables specifically designed for your plasma cutter. This can significantly enhance cutting speed and precision while reducing the frequency of replacements.

Additionally, ensure that your plasma cutting machine is operating at the recommended air pressure and temperature levels. Fluctuations can lead to inconsistent cuts and increased wear on components. Periodically calibrate your machine and adjust settings based on the material thickness and type to achieve optimal results.

**Tip:** Keep a maintenance log to track inspections, repairs, and part replacements. This practice provides insight into the machine's performance trends and helps in planning for future maintenance needs efficiently.

Plasma Cutting Machine Efficiency and Maintenance Best Practices

This chart illustrates the efficiency metrics of plasma cutting machines related to maintenance practices. It compares pre-maintenance and post-maintenance performance, optimal cutting speed, and energy consumption, highlighting the significant improvements that can be achieved through regular maintenance and best practices.

Maximizing Workflow: Tips for Organizing Your Plasma Cutting Work Area

Creating an organized plasma cutting work area is essential for maximizing workflow and enhancing efficiency. Start by assessing your workspace layout. Ensure that your plasma cutting machine has adequate space for movement and ventilation.

Position essential tools and materials within arm's reach to minimize unnecessary movement during the cutting process. This could involve using tool racks or storage bins that keep everything orderly and easy to access.

Maintaining a clutter-free environment allows for quick setups and prevents distractions, which ultimately leads to higher precision in your cuts.

Incorporating a systematic approach to workflow can also greatly impact your productivity. Implement regular reviews of your process and workspace, identifying any bottlenecks that might hinder performance.

For instance, organizing your materials by type or thickness can streamline your cutting processes and ensure that you spend less time searching for components.

Consider utilizing visual aids or checklists to help keep track of tasks and materials. By fostering an environment that prioritizes organization and efficiency,

you can harness the full potential of your plasma cutting machine, achieving both high-quality results and greater output.

Related Posts

-

Plasma Cutting Table Market Trends and Insights for Global Buyers 2025

-

Unlock Precision and Efficiency: Explore the Future with Plasma Laser Cutters for Modern Manufacturing

-

7 Reasons Why Cnc Plasma Cutters Are Essential for Modern Manufacturing Success

-

Ultimate Guide to Finding the Best Custom Plasma Cutting Solutions for Your Projects

-

Maximizing Value with Best Metal Plasma Cutter After Sales Support and Maintenance Cost Insights

-

Revolutionizing Global Manufacturing with the Best CNC Plasma Cutting Machine from China

English

English  Français

Français