Overflow Valve Block Essential Tips for Optimal Performance?

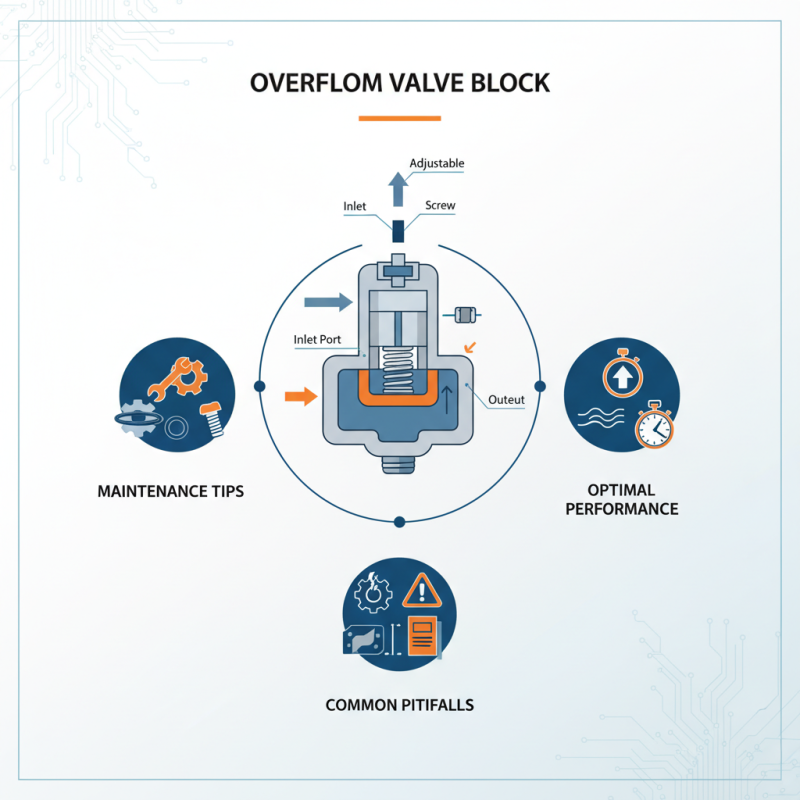

In the ever-evolving field of engineering, the "Overflow Valve Block" plays a pivotal role in system efficiency. According to industry expert Dr. Emily Carter, “The Overflow Valve Block is crucial for maintaining pressure balance in any hydraulic system.” This statement highlights the importance of understanding and optimizing this component for overall safety and functionality.

Proper maintenance of the Overflow Valve Block can seem daunting. Many professionals overlook simple adjustments that prevent failures. For instance, routine checks on seals and connections can mean the difference between smooth operations and costly breakdowns. Frequent inspections should not be neglected.

Optimal performance relies on awareness of common pitfalls. Insufficient cleaning or neglecting the manufacturer's specifications can lead to suboptimal functionality. Engineers must stay informed and adaptable. The lessons drawn from past experiences can guide future practices, ensuring that the Overflow Valve Block operates at its best.

Understanding the Functionality of Overflow Valve Blocks in Hydraulic Systems

Overflow valve blocks play a crucial role in hydraulic systems. They ensure pressure control and prevent system overload. Anomalies in performance can lead to severe problems. Recent industry reports indicate that improper maintenance can lower efficiency by up to 30%. This highlights the need for regular checks.

Understanding the specific functions of these valve blocks is vital. They regulate the flow of hydraulic fluid, allowing systems to function smoothly. If a valve fails, it can cause fluid leaks or pressure drops. These issues often go unnoticed until it's too late. Regular inspection can mitigate such risks.

Hydraulic systems demand precision and reliability. Inconsistent pressure can lead to equipment failures. Data shows that nearly 50% of hydraulic system failures stem from component malfunctions. Maintaining the overflow valve block is not just preventive but essential for optimal performance. Ignoring this can lead to costly repairs and downtime.

Key Performance Metrics for Overflow Valve Blocks: Optimal Flow Rates and Pressures

Overflow valve blocks play a critical role in maintaining optimal flow rates and pressures in various systems. Ensuring they operate efficiently requires an understanding of key performance metrics. Flow rates should align with system requirements. If rates are too high or too low, disruptions may occur, affecting the entire process.

Regular inspections can help identify issues early. Check for leaks or wear on seals. A small leak can lead to significant pressure drops. Maintaining proper pressure is essential for effective valve block performance. Consider a routine schedule for adjustments; oversights can lead to malfunction or failure.

Another important aspect is temperature management. High temperatures can affect the valve block's integrity. Monitoring this helps prevent unexpected breakdowns. Use thermal sensors to track changes. Make adjustments to cooling systems as needed. A proactive stance on potential risks fosters long-term efficiency. Validate your system's settings regularly to ensure everything operates smoothly.

Common Issues Impacting Overflow Valve Block Efficiency: Diagnosis and Solutions

Overflow valve blocks play a vital role in fluid systems. However, they can face various issues that impair performance. Common problems include sticking valves, leaks, and inconsistent pressure control. These can arise from contamination, wear and tear, or improper installation. A sticking valve may not respond to pressure adjustments as expected. This can cause over-pressurization or insufficient flow.

Diagnosing these issues requires careful inspection. Look for visible signs of wear or leaks. Check fluid viscosity and cleanliness; contaminants can create blockages. Sometimes, simply cleaning the valve block can restore functionality. However, if the issue persists, replacements may be necessary. It's essential to consider the root cause rather than only addressing symptoms.

Regular maintenance can significantly enhance performance. Keeping the valve block clean is crucial. Over time, even minor dirt accumulation can lead to major problems. Reflect on these factors; it’s easy to overlook simple solutions. A proactive approach can save time and resources while ensuring optimal efficiency. Emphasizing preventive measures is a step toward long-lasting performance.

Maintenance Best Practices for Extending the Lifespan of Overflow Valve Blocks

Overflow valve blocks play a crucial role in controlling system pressure. Regular maintenance is essential to keep them functioning optimally. Cleaning the valve block should be done periodically. Debris buildup can lead to improper functioning. Use a suitable solvent to ensure thorough cleaning. Inspect the components regularly for signs of wear. Rust or corrosion can compromise performance.

Checking the seals is also vital. Worn seals can lead to leaks. Replace them immediately to prevent further damage. Ensure that connections are tight; loose fittings can cause pressure drops. Monitoring system performance can help identify issues early. Listen for unusual noises that may indicate a problem.

Documentation of maintenance activities helps track the condition of the overflow valve block. Use a logbook to record each service performed. This practice can raise awareness of patterns or recurring issues. Regular training for personnel dealing with these systems can improve overall effectiveness. Encouraging a proactive maintenance culture is key for longevity.

Industry Standards and Compliance for Overflow Valve Design and Performance

When designing overflow valves, adhering to industry standards is essential. These standards ensure not only compliance but also performance efficiency. According to the Hydraulic Institute's latest report, a properly designed valve can reduce leakage rates by up to 30%. This translates to cost savings and enhanced safety in fluid systems.

Tips for optimal performance include regular maintenance checks. Inspections should be conducted every six months at minimum. Replace seals and gaskets as needed to prevent failures. Failure to meet these maintenance protocols can lead to significant losses. Indeed, 25% of reported malfunctions are due to poor upkeep.

Another critical point is the choice of materials. Corrosion-resistant materials can prolong the life of overflow valves. Nonetheless, many designs overlook environmental factors, risking premature wear. A balance between material durability and operational conditions is vital. Adopting flexible design approaches can improve compliance with evolving industry standards.

Overflow Valve Performance Metrics

This chart illustrates key performance metrics for overflow valves, including flow rate, pressure drop, temperature, and response time. Monitoring these metrics is essential for ensuring optimal performance and compliance with industry standards.

English

English  Français

Français