What is a Plasma Tube Cutter and How Does it Work?

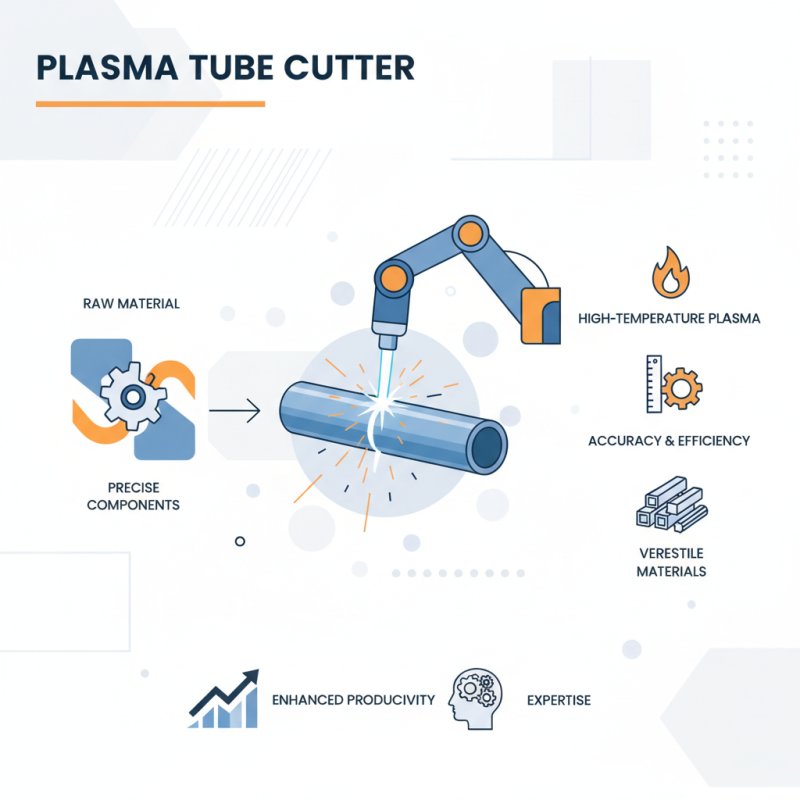

In the realm of metal fabrication, the Plasma Tube Cutter stands out. This cutting-edge tool revolutionizes how manufacturers process tubes. According to industry expert John Smith, "A Plasma Tube Cutter transforms raw materials into precise components."

The technology uses a high-temperature plasma arc to cut through metal quickly and cleanly. This method ensures accuracy, reducing wasted materials. Many workshops have adopted this tool for its efficiency. Still, some users find it challenging to master. The learning curve can be steep for new operators.

However, the benefits often outweigh the difficulties. A Plasma Tube Cutter can significantly enhance productivity. Its ability to handle various metal types also broadens its appeal. Understanding its technology is vital for those in the field. As the industry evolves, so does the need for expertise in using these tools effectively.

What is a Plasma Tube Cutter?

A plasma tube cutter is a specialized tool used for cutting metal tubes with precision. It utilizes plasma as a cutting medium, producing an intense heat that melts the material quickly. This method is efficient and clean, generating less waste compared to traditional cutting methods.

According to a recent industry report, the plasma cutting market has been growing steadily. It is projected to reach $5.5 billion by 2025, driven by increased demand in sectors like automotive and aerospace. Plasma tube cutters excel in creating intricate shapes and designs. They can cut through various materials, including stainless steel and aluminum, with thicknesses of up to 1 inch.

However, the technology is not without its challenges. Operators need to master the setup and calibration for optimal performance. Inadequate training can lead to uneven cuts or excessive waste. Users often report frustrations with settings, signaling the necessity for continuous education on the equipment. As the industry evolves, mindfully addressing these issues will be crucial for maximizing efficiency and effectiveness.

Plasma Tube Cutter Usage Statistics

Principles of Plasma Cutting Technology

Plasma cutting technology is a fascinating process. It utilizes a high-temperature plasma arc to cut through various materials. The principle behind plasma cutting is relatively simple yet ingenious. An electrical arc is formed by passing gas through a small nozzle. This gas, often compressed air or inert gas, becomes ionized and transforms into plasma.

The plasma reaches extreme temperatures, exceeding thousands of degrees Celsius. This intense heat melts the material, while the gas blows away molten metal, creating a clean cut. The accuracy of this technology is impressive. Intricate shapes can be cut with minimum waste. However, achieving the perfect cut requires practice and skill. A slight mistake in the angle can lead to uneven edges.

Despite its advantages, plasma cutting has its drawbacks. The setup can be complicated for beginners. Furthermore, safety precautions are necessary due to the high temperatures involved. Protective gear is essential to prevent burns and injuries. As technology evolves, improvements in plasma cutting are anticipated. Yet, the fundamentals remain unchanged, emphasizing the importance of understanding these core principles to maximize efficiency.

Key Components of a Plasma Tube Cutter

A plasma tube cutter is a specialized tool designed for cutting metal pipes and tubes. Understanding its key components helps in appreciating how it functions. The primary part is the plasma torch, which creates a high-temperature arc. This arc ionizes gas, turning it into plasma. The energy from the plasma cuts through metal quickly.

Another important component is the power supply. It provides the necessary energy to the plasma torch. Without a stable power source, the cutter can't operate effectively. Additionally, the setup often includes a cooling system to prevent overheating. This keeps the device operational for longer periods.

Users sometimes overlook maintenance needs. A well-maintained plasma cutter operates more reliably. Failing to check the gas flow can lead to poor cuts. Proper setup and calibration are essential for effective usage. The process requires practice and precision to achieve optimal results.

Applications of Plasma Tube Cutting in Various Industries

Plasma tube cutting is a remarkable technology used across various industries. This method is efficient for cutting through thick metal tubes and pipes. The process utilizes a jet of ionized gas, which quickly melts the metal. Industries like construction, automotive, and aerospace benefit greatly from plasma tube cutting. This technique allows for precise cuts without excessive heat deformation.

In construction, plasma cutters are essential for creating intricate designs. Builder teams can manufacture custom metal structures easily. The high-speed cuts save time and reduce labor costs. In the automotive industry, plasma cutting aids in producing complex shapes for vehicle parts. However, precision is crucial; minor errors can lead to waste.

Similarly, aerospace manufacturers use plasma cutting for lightweight components. The challenge lies in the tolerance levels required for safe and effective designs. Companies must continuously refine their processes. Balancing speed and accuracy is not always straightforward. Nonetheless, the advantages of plasma tube cutting continue to drive its adoption in various fields.

What is a Plasma Tube Cutter and How Does it Work? - Applications of Plasma Tube Cutting in Various Industries

| Industry | Application | Advantages of Plasma Cutting | Typical Materials Cut |

|---|---|---|---|

| Automotive | Chassis components, exhaust systems | High speed, precision cutting | Steel, aluminum |

| Aerospace | Wing structures, engine parts | Minimal thermal distortion | Titanium, high-grade alloys |

| Construction | Custom metal frameworks | Versatility in cutting shapes | Mild steel, stainless steel |

| Marine | Boat hulls, fittings | Ability to cut thick materials | Aluminum, carbon steel |

| Manufacturing | Production line components | Enhanced efficiency | Various metals |

Operational Efficiency: Speed and Accuracy in Plasma Cutting

Plasma cutting is known for its speed and precision. A plasma tube cutter utilizes a high-velocity jet of ionized gas to slice through metal. This method is not only efficient but also highly accurate. The cutter creates a focused arc that melts the metal. The plasma gas then blows the molten material away.

Operational efficiency is crucial for many industries. With a plasma tube cutter, the cutting speed can be impressive. Operators often achieve straight cuts without excessive labor. However, achieving perfect cuts requires practice. There can be inconsistencies in the cut quality if not handled correctly. Factors such as speed, power settings, and material thickness play an essential role.

The accuracy of the plasma tube cutter can significantly affect overall project timelines. If adjustments are not made, mistakes can occur. Sometimes, the cut edge may require additional finishing processes. This can lead to unexpected delays and cost overruns. Though plasma cutting is fast, it still requires careful attention and skill. A worker must constantly monitor settings for the best outcome.

Related Posts

-

Understanding the Importance of the Best Metal Plasma Cutter Technology

-

The Ultimate Guide to Selecting the Best Industrial Plasma Cutter for Your Business Needs

-

Unlock Precision and Efficiency: Explore the Future with Plasma Laser Cutters for Modern Manufacturing

-

Unveiling the Best Plasma CNC Machine Options for Your Business Needs

-

The Future of Plasma Torch Technology Revolutionizing Industrial Applications

-

Maximizing Value with Best Metal Plasma Cutter After Sales Support and Maintenance Cost Insights

English

English  Français

Français