What is Plastic Injection Mold and How Does It Work?

Plastic Injection Molding is a crucial manufacturing process widely used in various industries. Renowned expert in the field, Dr. Jane Thompson, states, "The efficiency of plastic injection molds reshapes how products are created today." This process allows for the rapid production of parts with great precision.

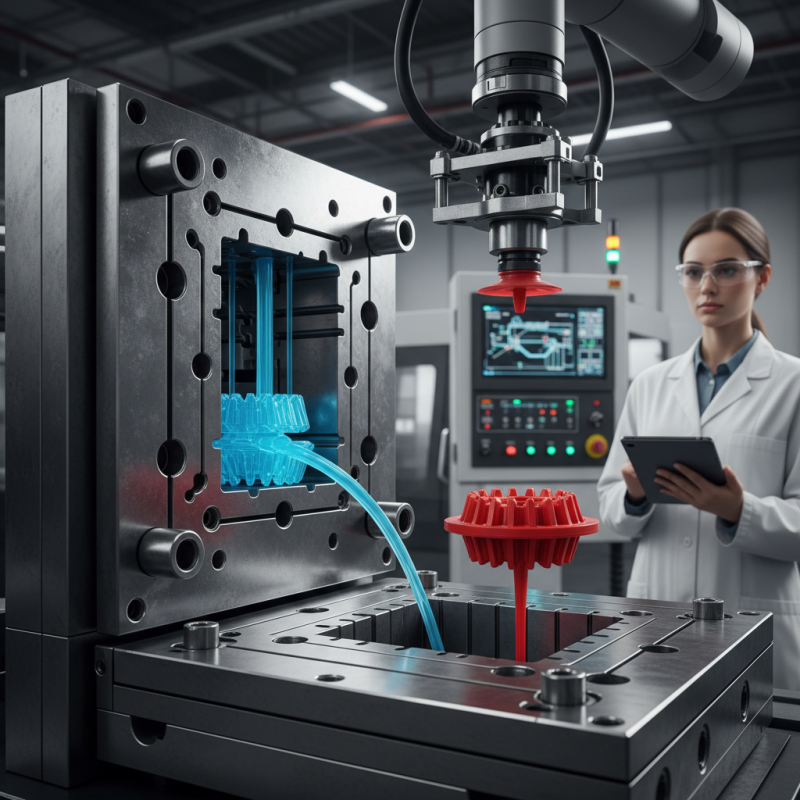

In simple terms, plastic injection molds inject molten plastic into a custom-made mold. The design of these molds is critical. A well-designed mold ensures that each product is consistent. However, not all molds meet these ideal standards. Minor flaws can lead to significant waste and inefficiencies.

Understanding plastic injection molds requires a keen eye for detail. The right materials and expert craftsmanship play vital roles in the outcome. Still, even experts face challenges. Factors like temperature and pressure need constant attention. This industry demands continuous improvement and reflection on practices.

What is Plastic Injection Molding? A Comprehensive Overview

Plastic injection molding is a crucial manufacturing process. It transforms raw plastic into various shapes and products. A machine heats plastic pellets until they melt. The molten plastic is then injected into a mold under high pressure. The mold is cooled, hardening the plastic into the finished part.

This process is versatile and efficient. It can produce simple items, like plastic containers, or complex components for machinery. However, it’s not without challenges. The design of the mold can be intricate and expensive. Poor design can lead to defects in the final product. Adjustments may be necessary to achieve the desired precision.

Injection molding requires careful monitoring. Even minor errors during production can result in waste. Operators must be trained to spot issues early. It's a balance of speed and quality, where mistakes can be costly. Success relies on precision and attention to detail. Otherwise, the results may fall short of expectations.

What is Plastic Injection Mold and How Does It Work?

| Dimension | Specification |

|---|---|

| Mold Material | Tool Steel, Aluminum |

| Injection Pressure | 500 - 30,000 psi |

| Cycle Time | 15 - 60 seconds |

| Typical Dimensions | 1 mm to several meters |

| Common Plastics Used | ABS, Polypropylene, Polyethylene |

| Applications | Automotive, Consumer Goods, Medical Devices |

Key Components of Injection Molding Machines and Their Functions

Injection molding machines are essential for producing plastic parts. Understanding their key components is crucial for efficient operation. Each part plays an important role in the molding process.

The hopper is where raw plastic pellets enter the machine. This component feeds the material into the barrel. The screw inside the barrel mixes and melts the pellets into a liquid form. Inadequate feeding may cause inconsistent quality.

The mold itself shapes the melted plastic. It consists of two halves that come together during the injection process. Temperature control is vital here. Improper temperatures can lead to defects like warping. Regular maintenance of molds is essential to avoid costly mistakes.

**Tip:** Always monitor the fluidity of the melted plastic. This can prevent issues down the line. Cleaning the hopper and barrel regularly can also improve performance. Don't overlook these basic steps; they can save time and resources.

The Injection Molding Process: Step-by-Step Breakdown

The injection molding process is a widely used method for creating plastic parts. This technique involves several key steps that combine precision and efficiency. First, raw plastic material is heated until it becomes molten. The temperature typically exceeds 200 degrees Celsius, depending on the type of plastic. Then, this molten material is injected into a mold under high pressure, which can reach up to 30,000 psi. This high-pressure technique ensures that the material fills every cavity of the mold, producing detailed shapes.

After the plastic cools and solidifies, the next step is ejection. The mold opens, and the finished product is ejected. This process can take mere seconds for simple shapes. However, complexity can lead to longer cycle times. Industry reports suggest that cycle times can average 15 to 60 seconds, depending on the part's size and design. It’s a fast but complex process that requires precision. Not all designs are optimal. Some parts may require redesign due to warping or uneven cooling.

Quality control is critical throughout the process. Ensuring the right temperatures and pressures can affect the final product's integrity. Unexpected issues may arise, prompting engineers to revisit the design phase. Continuous improvement is essential for efficiency. It is vital to assess each production run to refine techniques and minimize waste.

Material Choices in Plastic Injection Molding: Properties and Specifications

Material choices in plastic injection molding significantly impact the quality and performance of the final product. Several materials are commonly used, including thermoplastics and thermosetting plastics. Thermoplastics, like ABS and polycarbonate, offer excellent versatility. They are easy to mold and recycle, making them a popular choice among manufacturers. In contrast, thermosetting plastics, such as epoxy and phenolic, provide superior thermal stability but are more challenging to work with.

The properties of these materials vary widely. For instance, ABS has a tensile strength of around 40 MPa, making it suitable for durable applications. Polycarbonate, however, can withstand impacts better, with a strength reaching up to 70 MPa. According to a report by the Plastics Industry Association, nearly 33% of all plastic parts produced in 2021 were made from standard polymers like these. Each material’s specifications determine its use in different applications, ranging from automotive components to consumer electronics.

Despite the advantages, there are challenges. Selecting the right material requires a deep understanding of the project's requirements. A poor choice can lead to product failure, affecting durability and performance. Some manufacturers may overlook this aspect, resulting in higher costs and rework. Balancing material properties with production techniques is crucial. As industry standards evolve, a more informed approach to material selection is needed.

Industry Applications of Plastic Injection Molding: A Data-Driven Perspective

Plastic injection molding has become a cornerstone in various industries. In 2022, the global market for this process was valued at approximately $220 billion. Projections suggest it will reach $300 billion by 2028, driven by demand for lightweight yet durable products. Industries like automotive, consumer goods, and healthcare lead the way in adoption, showcasing the process's versatility.

In the automotive sector, plastic injection molded parts account for about 30% of vehicle components. This method enables the production of complex geometries quickly. Healthcare applications are notable as well. With a projected growth rate of 6% annually, the need for precision and hygiene in medical devices drives innovation in molding techniques. However, environmental concerns arise. The challenge remains in recycling these plastics efficiently.

Despite advancements, defects still occur. In about 3-5% of projects, manufacturers encounter issues like warping or incomplete filling. This reflects the need for continuous improvement and better quality control measures. Companies must not only focus on speed and cost but also on sustainability and reducing waste. The industry must adapt to changing consumer preferences for greener products.

English

English  Français

Français