Revolutionizing Global Manufacturing with the Best CNC Plasma Cutting Machine from China

In recent years, the manufacturing landscape has witnessed a dramatic transformation, largely driven by advancements in technology and automation. Among these innovations, the CNC Plasma Cutting Machine stands out as a pivotal tool that enhances precision and efficiency in material processing. According to a report by Markets and Markets, the global CNC plasma cutting machine market is expected to grow from USD 3.1 billion in 2021 to USD 4.5 billion by 2026, reflecting a compound annual growth rate (CAGR) of 7.5%. This growth is primarily fueled by the increasing demand for automation in manufacturing processes across various sectors such as automotive, aerospace, and metal fabrication. As manufacturers seek to improve productivity and reduce operational costs, investing in high-quality CNC plasma cutting technology, particularly those emerging from China, promises to revolutionize traditional manufacturing methodologies and set new benchmarks for quality and efficiency in the industry.

The Rise of CNC Plasma Cutting Technology in Global Manufacturing

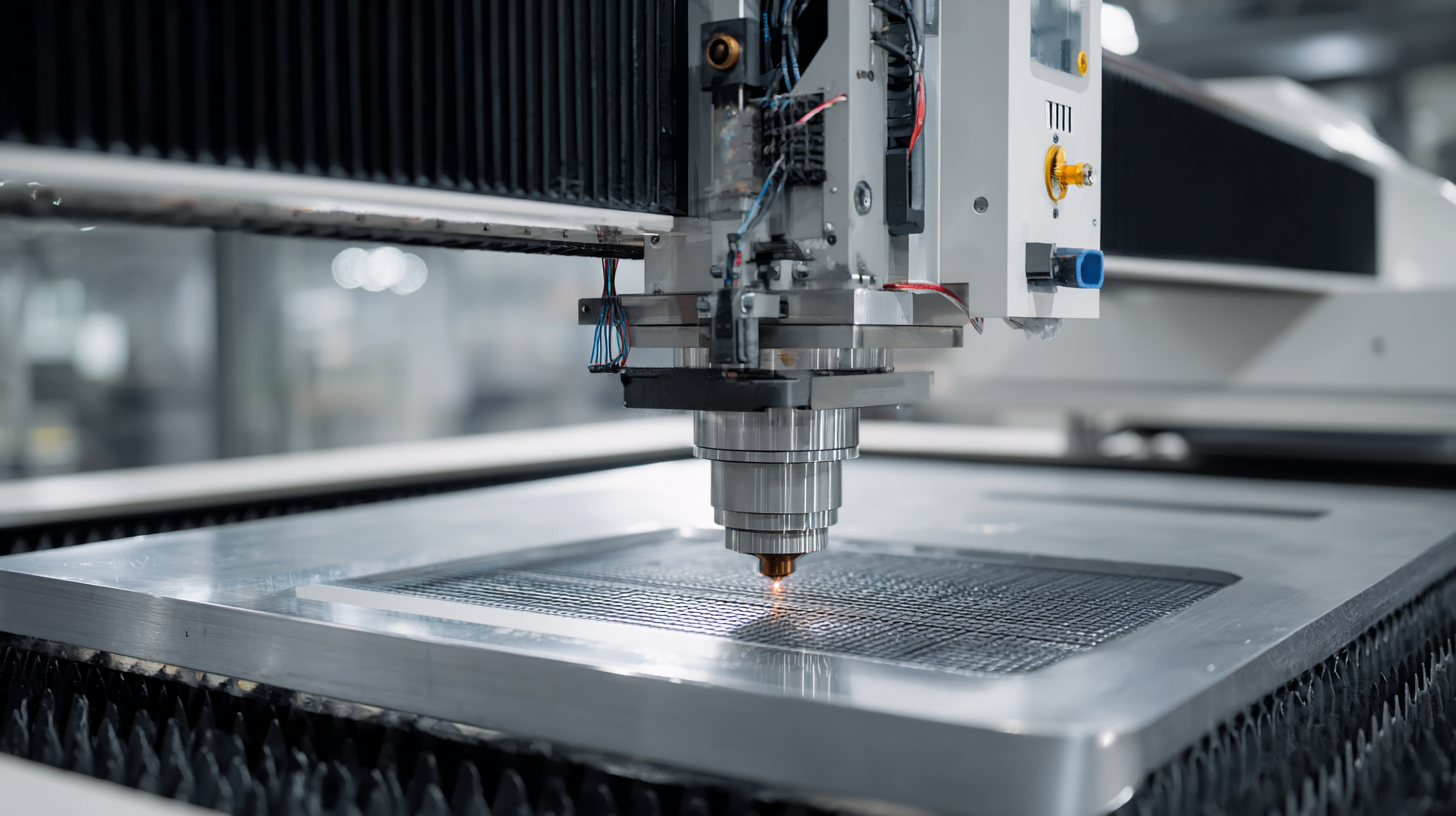

The rise of CNC plasma cutting technology is transforming the landscape of global manufacturing. This innovative technique utilizes high-velocity jets of plasma to cut through metal with remarkable precision and efficiency. As industries strive for higher productivity and superior quality, CNC plasma cutting has emerged as a game-changer, streamlining processes across various sectors, from automotive to aerospace. With speed and accuracy at its core, this technology not only reduces waste but also minimizes labor costs, allowing manufacturers to remain competitive in an increasingly global market.

The rise of CNC plasma cutting technology is transforming the landscape of global manufacturing. This innovative technique utilizes high-velocity jets of plasma to cut through metal with remarkable precision and efficiency. As industries strive for higher productivity and superior quality, CNC plasma cutting has emerged as a game-changer, streamlining processes across various sectors, from automotive to aerospace. With speed and accuracy at its core, this technology not only reduces waste but also minimizes labor costs, allowing manufacturers to remain competitive in an increasingly global market.

Chinese manufacturers are at the forefront of this revolution, producing some of the best CNC plasma cutting machines available today. These machines are equipped with advanced features such as automated controls, better software integration, and enhanced safety protocols, making them highly sought after worldwide. By adopting these cutting-edge machines, manufacturers can achieve faster turnaround times, lower operational costs, and improved product quality. As a result, the global manufacturing sector is witnessing an unprecedented shift towards embracing CNC plasma cutting technology, driving innovation and efficiency across the board.

Key Features and Benefits of Advanced CNC Plasma Cutting Machines

The rapid advancement in CNC plasma cutting technology is reshaping global manufacturing, particularly with the introduction of advanced machines from China. These state-of-the-art CNC plasma cutting machines come equipped with automatic nesting software, which plays a crucial role in reducing operational costs and minimizing material waste. By optimizing the layout of cuts, this intelligent feature enhances productivity and results in better resource management, making it an indispensable tool for modern fabricators.

Moreover, the increasing demand for high-precision, multi-axis machining centers is driving significant growth in the CNC machine tools market. As industries evolve and transition from manual to automated machining processes, the smart automation features of the latest CNC plasma cutting machines are enabling manufacturers to meet the rigorous demands of precision manufacturing. With China emerging as a leader in innovation, the features of these advanced machines are not only enhancing efficiency but also pushing the boundaries of what is possible in metal fabrication.

Market Trends and Predictions for the CNC Plasma Cutting Industry by 2025

The CNC plasma cutting machine market is poised for significant growth as industries worldwide continue to embrace automation and precision. By 2025, experts predict that the market will reflect robust advancements, driven by increasing demand for high-quality metal fabrication and a surge in new manufacturing technologies. This trend is largely attributed to the shift towards more efficient production processes that can handle complex tasks with minimal waste. As businesses seek to optimize their operations, CNC plasma cutting machines are becoming indispensable tools in various applications, including automotive, aerospace, and heavy machinery manufacturing.

Additionally, the impact of the COVID-19 pandemic has accelerated the need for modernization in manufacturing settings. As companies reevaluate their operational strategies, investing in CNC technology offers a way to enhance productivity while maintaining safety protocols. This evolving landscape is reflected in the market's increasing size and share, suggesting that by 2025, CNC plasma cutting machines will not only revolutionize manufacturing processes but also position themselves as key drivers of competitive advantage in a rapidly changing global market. The focus on automation and high efficiency will undoubtedly shape the future of the CNC plasma cutting industry, making it a critical area to watch in the years to come.

How to Choose the Right CNC Plasma Cutting Machine for Your Business

When selecting the right CNC plasma cutting machine for your business, there are several crucial factors to consider. First and foremost, assess your specific cutting needs, including the types of materials you'll be working with and the thickness of the materials you frequently handle. Different machines are designed to accommodate varying material types, such as steel, aluminum, or even more exotic materials. Understanding the nuances of your projects can help narrow down options and ensure you choose a machine that enhances your operational efficiency.

Another important aspect is the machine’s features and capabilities. Look for a CNC plasma cutting machine that offers advanced technology, such as automatic height control and precise motion systems. These features can significantly improve cutting quality and speed, leading to smoother operations and less waste. Furthermore, consider the available support and training from the manufacturer. A reliable supplier should provide comprehensive assistance, including installation, maintenance, and operator training, ensuring that you can fully leverage the machine's capabilities for your business growth.

Best Practices for Integrating CNC Plasma Cutting into Your Production Line

Integrating CNC plasma cutting into your production line can significantly enhance efficiency and precision in manufacturing. To begin, it’s essential to assess your current workflow and identify areas where CNC plasma cutting can be the most beneficial. This technology excels in cutting various materials with incredible speed and accuracy, making it a perfect choice for industries ranging from automotive to aerospace. By integrating this machine, you can reduce material waste and shorten production times, leading to cost savings and increased productivity.

Once the CNC plasma cutting machine is selected, proper training for your operators is crucial. Educated staff will not only ensure safe operation of the machine but will also maximize its capabilities. Establishing best practices for maintenance and operation will prolong the life of the equipment and enhance overall performance. It is also advisable to continuously monitor the integration process, collecting data on output quality and production rates to refine techniques and identify any bottlenecks. This proactive approach will enable manufacturers to stay competitive in a global market while harnessing the full potential of CNC plasma cutting technology.

Revolutionizing Global Manufacturing with the Best CNC Plasma Cutting Machine from China

| Feature | Specification | Industry Application | Efficiency | Estimated Cost |

|---|---|---|---|---|

| Cutting Thickness | 1 mm to 40 mm | Metal Fabrication | High | $10,000 - $30,000 |

| Cutting Speed | Up to 8 m/min | Automotive | Very High | $12,000 - $25,000 |

| Control System | CNC with Software Integration | Aerospace | Moderate | $15,000 - $35,000 |

| Precision | ±0.5 mm | Construction | High | $11,000 - $28,000 |

| Power Supply | Plasma Arc Technology | Shipbuilding | High | $20,000 - $40,000 |

English

English  Français

Français