Professional fabricators have choices when it comes to burn tables used for processing materials. Two of the most common types are oxy-fuel and plasma cutters. Both offer powerful cutting technology but function in different ways. Understanding how they work and the advantages and disadvantages of each can help you determine which is the better option for your shop.

Difference Between Plasma & Oxy Fuel Cutting

Oxy fuel and plasma cutters are used for different types of fabrications because of how the torch is fueled. Let’s take a closer look at how an oxy fuel and plasma torch works.

Oxy Fuel Torch

Before actual cutting begins, an oxygen-fueled flame preheats the material (a process that creates liquefied iron oxide called slag). Once the metal reaches its ignition point, a powerful jet of oxygen pushes through the preheated area to complete the cut.

Plasma Torch

Plasma torches electrically charge compressed air to create a conductive stream of heated gas. The flame produced by a plasma torch is so hot that it literally melts the material, creating a smooth edge and a polished appearance.

Advantages of Oxy Fuel Cutting

Oxy fuel cutting machines are ideal for fabricating thick materials measuring more than one inch. They also allow for certain types of processing that cannot be performed on other cutting systems. These include fusion welding of ferrous metals, heat shaping, heat treating, soldering, brazing, and riser cutting.

Disadvantages of Oxy Fuel Cutting

Oxy fuel cutting is most effective on ferrous, or iron-containing, materials; therefore, it’s not commonly used for processing stainless steel or other nonferrous metals. Additionally, oxy cutting takes more time than plasma cutting, and it does not handle thinner materials well.

Advantages of Plasma Cutting

Plasma cutting machines are capable of processing nonferrous metals, such as stainless steel and aluminum, two materials that are commonly used in many different applications across a range of industries. Plasma cutting is also a faster process than oxy fuel cutting and can help speed up production.

Disadvantages of Plasma Cutting

Because the plasma flame is electrically charged, plasma burn tables can only process conductive metals like mild steel, carbon steel, stainless steel, expanded steel, copper, and brass. Furthermore, plasma cutting is less effective at fabricating thick materials.

Which Is the Right Choice for Your Shop?

Determining whether an oxy fuel or plasma cutter is the right choice for your shop can be made easier when you think about what kind of fabrications you specialize in. It’s also worth keeping in mind any expanded capabilities you may be looking into for the future. Selecting a burn table that can meet your immediate needs and grow along with your business is integral to ensuring quality work and speedy turnarounds at your shop.

Our Experts Can Help

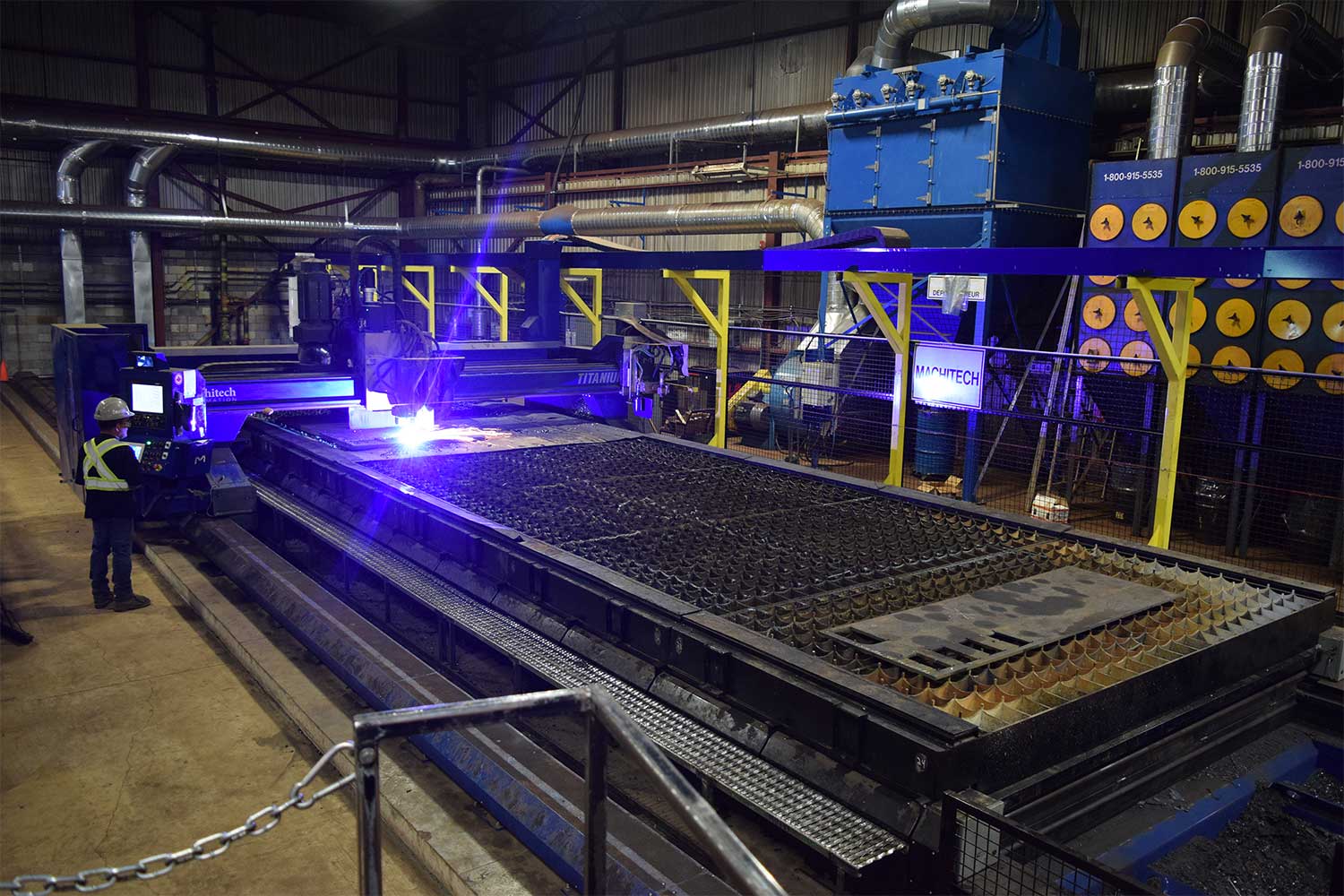

Machitech is a leading manufacturer of heavy-duty burn tables for custom fabrications. Our solutions feature CNC controls to automate operations and include free and unlimited support for life. To speak with a representative about finding the ideal precision cut table for your shop, contact us today.

English

English  Français

Français