Plasma cutting systems have long been a cornerstone of industrial progress. Their ability to cut through conductive metals quickly and accurately has made them indispensable across sectors like manufacturing, construction, shipbuilding, and automotive production. These tools have empowered fabricators to meet high production demands while maintaining precise tolerances, playing a critical role in scaling operations and driving innovation.

Today, as industries continue to evolve with greater demands for efficiency and precision, the expectations for fabrication equipment are also rising. In the article below, we’ll explore how the next generation of plasma cutters is expected to continue spurring industrial growth.

A Brief History of Plasma Cutting Systems in Fabrication

Plasma cutting emerged during the mid-20th century as a groundbreaking alternative to oxy-fuel cutting. Initially developed for high-speed and high-precision military manufacturing, plasma cutters quickly gained traction because of their ability to slice through stainless steel, aluminum, and other conductive materials with ease.

Compared to traditional methods like mechanical sawing or flame cutting, plasma cutting systems introduced a cleaner, faster, and more efficient process. Over time, their use expanded across various industries, thanks to their ability to deliver high-quality cuts with minimal distortion. As digital controls and automation became more integrated into manufacturing, CNC plasma cutting systems began to dominate metal fabrication environments—paving the way for today’s advanced solutions.

Innovations Driving the Future of Plasma Cutting

The next generation of plasma cutting systems is being shaped by advancements in automation, artificial intelligence, and precision engineering. These innovative technologies aim to reduce waste, improve accuracy, and deliver faster cycle times, even in demanding production environments.

One of the major trends in next-gen plasma technology is adaptive cutting, where real-time data and sensors are used to automatically adjust parameters such as speed, arc voltage, and torch height. This leads to more consistent results, even with variable material thicknesses. Another area of growth is the integration of AI-driven diagnostics, which can detect wear on consumables and reduce unplanned downtime.

Together, these fabrication advancements are positioning plasma cutting as a highly efficient and scalable solution for the future of industrial manufacturing.

Machitech’s Plasma Cutting Systems: Setting the Standard

Machitech continues to lead the way in plasma cutting innovation thanks to our comprehensive line of CNC plasma cutting systems. Designed to meet the needs of both growing shops and large-scale industrial operations, Machitech systems combine innovative software, robust build quality, and customizable configurations to deliver exceptional results.

Among our PlasmaTable™ Series offerings are:

- SilverCut™ – Designed for businesses seeking a balance between performance and value, this system includes an easy-to-use operator console and customizable bed sizes.

- GoldCut™ – Tailored for high-capacity shops, this series offers table sizes up to 10 feet by 40 feet and advanced nesting software for optimized material usage.

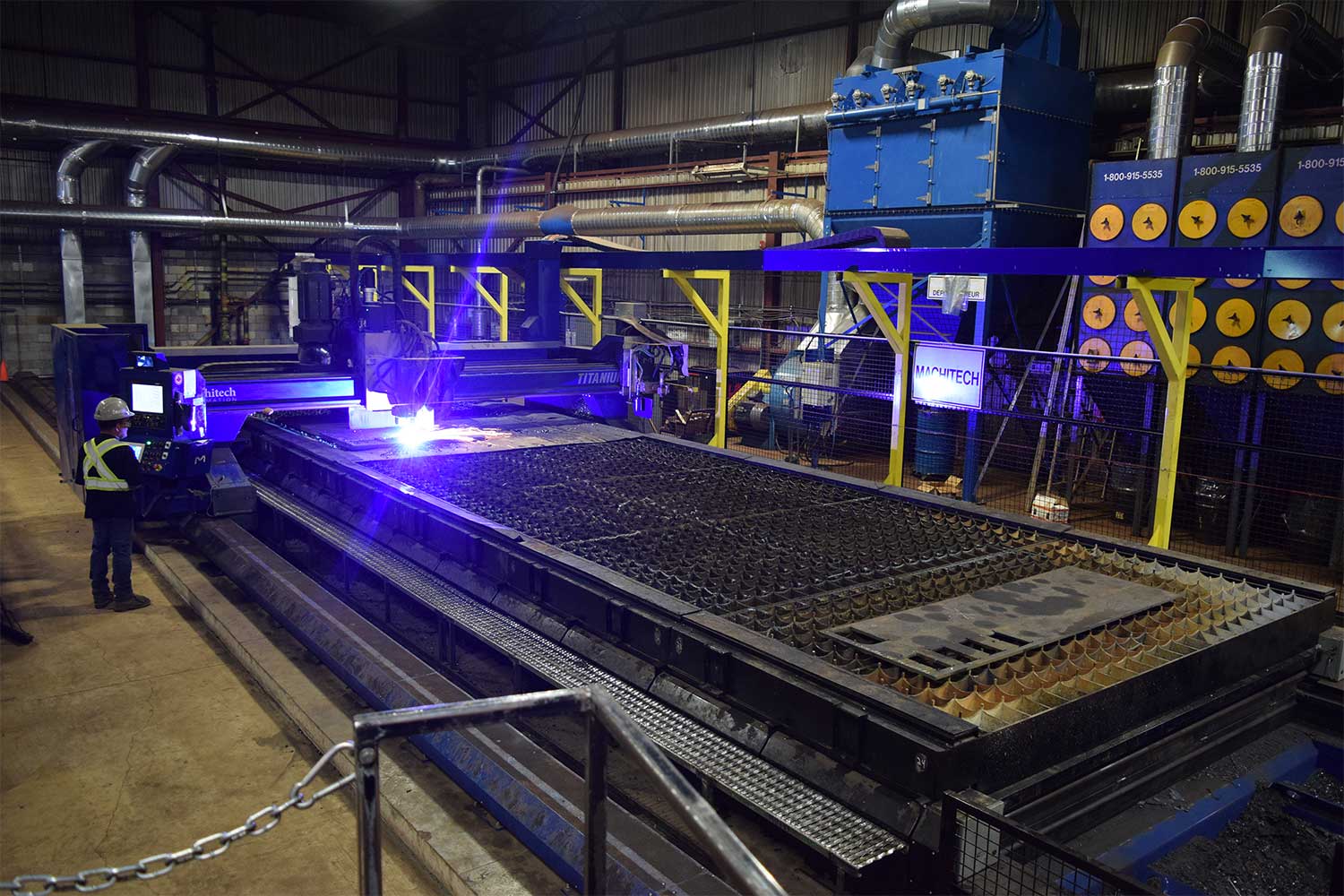

- Titanium Cut™ – A fully automated industrial plasma system featuring a welded frame and the HyPerformance® HPR400XD plasma system.

Each Machitech system features a user-friendly CNC controller, customizable options, and compatibility with future-ready cutting solutions. Our ability to deliver advanced fabrication tools backed by responsive service and expert engineering continues to set us apart in the competitive plasma cutting landscape.

Machitech plasma cutting systems offer the precision and dependability needed for today’s industrial growth—and the scalability to adapt for tomorrow.

Discover Future-Ready Cutting Solutions Today

Machitech is not just keeping pace with the evolution of plasma cutting—it’s helping drive it. With an unmatched commitment to customization, and innovation, Machitech offers next-gen plasma technology designed to help fabricators meet the growing demands of modern industry.

Contact us today to learn more or request a quote for your next cutting solution.

English

English  Français

Français