Carbon steel and stainless steel have countless applications and are two of the most common materials that custom fabricators work with. Both materials are extremely durable, but each can be more durable than the other depending on the application. Let’s take a closer look at carbon steel and stainless steel and learn where they excel in terms of durability.

Carbon Steel

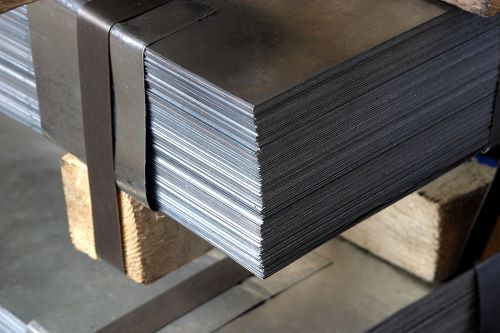

Steel is an alloy of iron that contains carbon, which gives it strength. Carbon steel can withstand considerable force before breaking. The sturdiness of this material makes it ideal for maintaining shape and resisting abrasion, which is why carbon steel is widely used for fabricating industrial tools, plates, bolts, and hull panels for shipbuilding.

Even though carbon steel can absorb strong forces, it does have a breaking point and will eventually succumb to pressure. This is where carbon steel is at a disadvantage over softer steels—it is often brittle and will crack, rather than bend, under pressure. The level of carbon can be adjusted, however, with low-carbon steels offering more flexibility than high-carbon steels.

Stainless Steel

In addition to iron and carbon, stainless steel contains chromium, which is naturally resistant to corrosion and rusting. This element is what allows stainless steel to be used in environments where moisture may be present, such as in kitchens and on ships, as it can last for years without corroding.

How Does the Presence of Chromium in Stainless Steel Impact its Durability?

The incorporation of chromium in stainless steel plays a pivotal role. It forms a protective oxide layer on the steel’s surface, known as passive film, which acts as a shield against corrosion, rust, and other environmental factors. This passive film not only adds a remarkable resistance to tarnishing but also contributes to the overall strength and longevity of stainless steel. The presence of chromium transforms stainless steel into a robust material capable of withstanding harsh conditions, making it an ideal choice for various applications where durability is paramount, from kitchen appliances to industrial equipment. Adding chromium, however, can drive up the costs of stainless steel.

What Distinguishes Carbon Steel From Stainless Steel in Terms of Durability?

To answer the question of whether carbon steel or stainless steel is more durable ultimately depends on the application. If the material is expected to maintain its shape under intense pressure, carbon steel will outperform stainless steel, which will distort much sooner. If the material is to be used on a ship, in a pumping system, or in another application where it may come into contact with water, stainless steel will prevent corroding, whereas carbon steel may quickly rust and degrade.

To answer the question of whether carbon steel or stainless steel is more durable ultimately depends on the application. If the material is expected to maintain its shape under intense pressure, carbon steel will outperform stainless steel, which will distort much sooner. If the material is to be used on a ship, in a pumping system, or in another application where it may come into contact with water, stainless steel will prevent corroding, whereas carbon steel may quickly rust and degrade.

What Factors Influence the Choice Between Carbon Steel & Stainless Steel in Fabrication?

Though their chemical makeup and intended applications are different, both carbon steel and stainless steel are in high demand across numerous industries. Professional custom fabricators need to be adept at working with both materials to get ahead in the industry.

The choice between carbon steel and stainless steel in fabrication is influenced by several factors. Firstly, the environmental conditions and exposure to corrosive elements significantly impact the decision. Secondly, the required strength and durability play a pivotal role. Cost considerations also weigh in, as stainless steel tends to be pricier than carbon steel. Additionally, aesthetic preferences, ease of fabrication, and the intended application’s specific requirements collectively guide the decision-making process between these two materials.

Why Are CNC Plasma Cutting Machines From Machitech Recommended for Working With Both Carbon Steel & Stainless Steel?

CNC plasma cutting machines from Machitech are an excellent choice for both carbon steel and stainless steel due to their advanced features and precision engineering. Machitech’s cutting systems are designed with versatility in mind and can be seamlessly adapted for a variety of materials, including carbon steel and stainless steel. Our use of cutting-edge technology ensures precise and efficient cuts on both materials, making our CNC plasma cutters a reliable choice for an array of industries.

Schedule a Consultation With Our Team

Machitech is a leading manufacturer of automated CNC plasma cutters that can provide your shop the equipment it needs to reach the next level of success. Plus, our CNC plasma machines come with free and unlimited lifetime support from our professional team. To learn more, contact Machitech today.

English

English  Français

Français