Plasma cutters have a reputation in the industry for producing clean and accurate cuts. While this is certainly true, the accuracy of plasma cutting largely depends on the setup of the system. For instance, a handheld torch will never produce cuts as accurate as those made by an automated computer numerical control (CNC) plasma cutting machine. But even under the vast umbrella of CNC plasma cutting technology, there are variables that can affect accuracy.

Plasma Cutting By Hand

There are countless fabrication experts out there who have made a career of processing materials with a handheld torch. Backed by years of experience, these professionals can produce cuts within 1.6 millimeter tolerance. Superb hand control is a hallmark trait of a skilled fabricator, but no matter how good they are, there is just no comparing to the accuracy produced by a computer-controlled machine.

Precision Plasma Cutting Machines

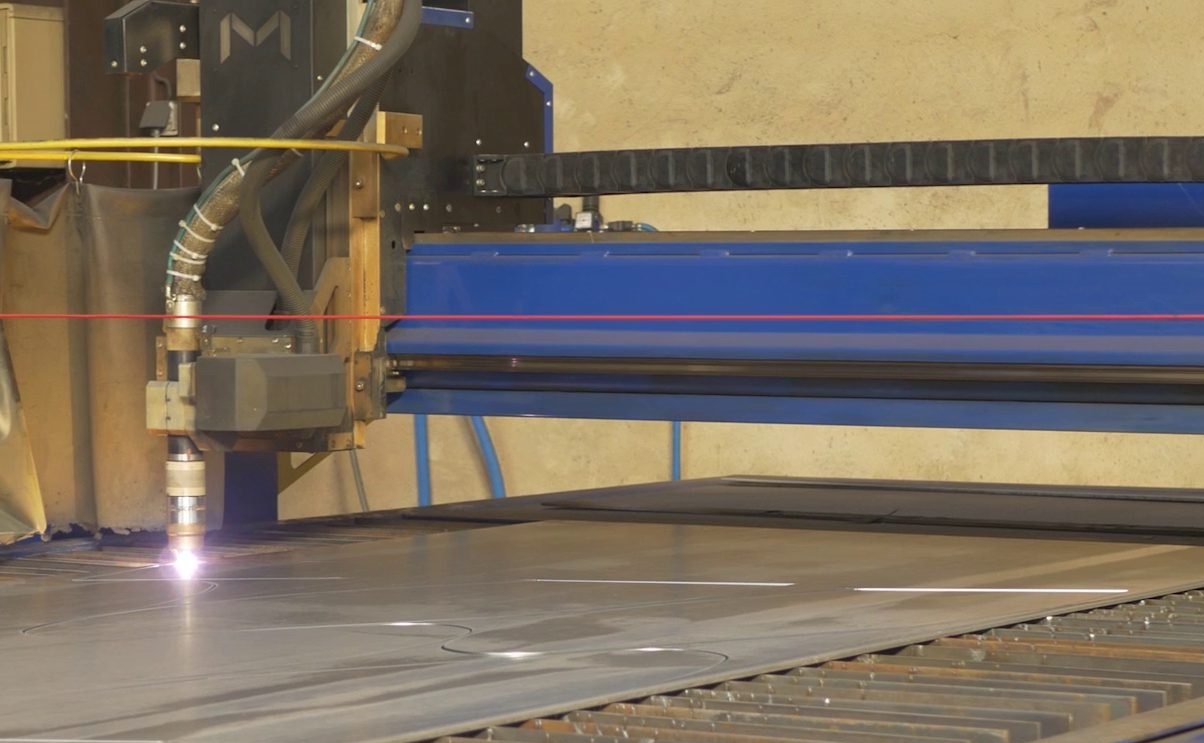

CNC plasma cutters are used for myriad applications and therefore come in a wide range of sizes and capabilities. The accuracy of the cuts produced on these systems depends on the plasma source, CNC software, and other features.

Entry-Level & Light-Industrial Systems

Entry-level plasma cutting tables, typically used by small shops and amateur hobbyists, can process materials within a plus or minus .77 millimeter tolerance. Light-industrial CNC burn tables are more durable than entry-level models and used for low-level to moderate processing. These plasma cutters produce edge tolerances within the .38 to .64 millimeter range.

Heavy-Industrial Systems

Built for mass production, heavy-industrial plasma cutters can run throughout the day. These heavy-duty systems include powerful features to deliver more accurate cuts with tolerances from .25 to .51 millimeters (depending on the material and its thickness). What heavy-industrial and light-industrial systems have that entry-level models don’t is automated torch height control, an integral feature for maintaining accuracy of plasma cutting.

Importance of Automated Torch Height Control

All CNC plasma cutting tables have an x and y axis, but light- and heavy-industrial machines have a third, z axis. The movement of the torch on the vertical z axis allows the plasma cutter to automatically adjust to the wear of the material. For instance, aluminum is thin and tends to bow while being processed. Automatic torch height control can react to the changing shape of the material and move the torch out of its way, preventing negative and positive cut angles that would then need to be grinded down.

Another Factor That Can Affect Accuracy: Beveling

Plasma torches produce clean and smooth edges. However, because the ionized air swirls out of the torch in an arcing motion, a small bevel is created on the cut face. This makes the surface edge of the cut slightly more accurate than the bottom. The swirling appearance of the cut face is hardly noticeable on materials thinner than 3 millimeters but is more pronounced on materials 6 millimeters or thicker.

Finding the Right CNC Plasma Cutter for Your Shop

Machitech is the leading manufacturer of heavy-duty precision CNC plasma cutting machines for custom fabrications. We know how important accuracy is when producing parts, which is why we will design your burn table to match your exact needs. To learn more, contact Machitech today and be sure to ask about the free and unlimited lifetime support that we’ll include with your purchase.

English

English  Français

Français