When it comes to metal fabrication, it often seems like the majority of technology has been around for decades with some minor changes and updates. While some technology will always produce a great cut and be an excellent choice for a metal fabrication shop, there is a constantly evolving world of technology. In recent years fiber laser cutting has grown in popularity amongst metal fabricators. There are many reasons for this, but to truly understand why it has become so popular, it is important to understand what fiber laser cutting is and what differences it brings to the table. When compared with other methods of metal fabrication, fiber laser cutting is an innovative technology.

CNC Fiber Laser Cutting Explained

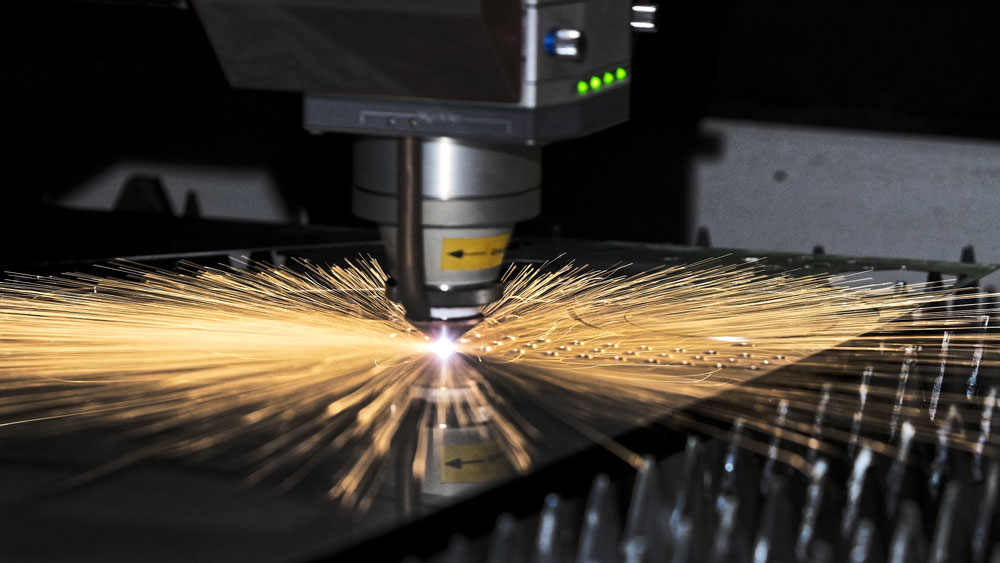

CNC fiber laser cutting is a precise and efficient process that utilizes fiber optic lasers to cut through a variety of metals, including steel, aluminum, and brass. The fiber laser generates a highly concentrated beam of light, which is directed through a fiber optic cable, delivering intense energy to a focal point on the metal surface. This results in rapid heating, melting, and vaporizing of the material, producing clean, accurate cuts.

Compared to traditional CO2 and plasma laser cutters, fiber laser cutting systems offer several advantages. Unlike CO2 lasers, which use gas to create the laser beam, fiber lasers are entirely solid-state, meaning they require less maintenance and operate with greater energy efficiency. Fiber lasers also deliver faster cutting speeds and better precision, especially for thin materials. Plasma cutting, while effective for thicker metals, lacks the precision and cost-effectiveness of CNC fiber laser cutting, making fiber lasers the preferred choice for manufacturers seeking high performance.

An Increasingly Popular Metal Fabrication Option

Fiber lasers have grown in popularity so significantly because they can be used in a wide range of industries for a variety of materials. CNC fiber laser cutting can be used on materials such as mild steel, stainless steel, aluminum, brass, copper, titanium, ceramics, graphite, composites, silicon, coated and plated metals, opaque plastics, and more. Fiber laser cutting is precise, efficient, low-maintenance, and easy to on-board in any facility.

CNC Fiber Laser Cutters From Machitech

Machitech offers advanced CNC fiber laser cutters through Alpha Lazer. These fiber laser cutting systems are equipped with high-power fiber optic lasers, ranging from 1kW to 15kW, providing exceptional cutting speeds and precision. They also feature automated material handling systems, making production faster and more efficient. The fully enclosed cutting area ensures operator safety while reducing environmental impacts.

Thanks to user-friendly CNC controls, operators can manage complex cutting patterns with ease. Alpha Lazer’s systems are designed to handle a wide range of metals, ensuring versatility and optimal performance for diverse industrial applications.

Discover the Power of CNC Fiber Laser Cutting

Could your shop benefit from the advanced production capabilities a CNC fiber laser cutter can provide? Contact Machitech today to learn more about our innovative fiber laser cutting systems and how they can transform your manufacturing process.

English

English  Français

Français