For commercial and industrial businesses looking for ways to improve efficiency and accuracy in their fabrication processes, investing in a CNC plasma pipe cutting machine could be the key to boosting profitability. These machines offer precision and speed, making them an attractive option for companies that rely heavily on pipe cutting for their projects. If you’re wondering how a CNC plasma pipe cutting machine might improve your bottom line, this article will address some common questions and explore the benefits of this advanced technology.

How Do CNC Plasma Pipe Cutters Function?

CNC plasma pipe cutting machines use a high-velocity jet of ionized gas (plasma) to cut through metal pipes with precision. The process starts when an operator inputs the design specifications into the CNC (Computer Numerical Control) system. This system guides the plasma torch, ensuring that each cut is accurate and matches the programmed design. The plasma itself is created by sending compressed air through an electric arc, which heats the gas to a point where it becomes ionized and capable of cutting through even thick metal pipes.

Who Utilizes CNC Plasma Pipe Cutters?

CNC plasma pipe cutting machines are highly versatile and serve a range of industries. Here are a few key sectors that can benefit from integrating these machines into their operations:

- Oil and gas – Plasma pipe cutting machines are commonly used to cut and shape pipes for pipelines, refineries, and other infrastructure projects.

- Construction – In this industry, CNC plasma pipe cutters are vital for creating structural components, supports, and frameworks.

- Manufacturing – Industrial pipe cutting machines are essential in the production of parts for machinery, vehicles, and industrial equipment.

- Shipbuilding – The precision offered by CNC plasma pipe processing machines makes them ideal for cutting and shaping pipes used in marine construction.

Whether you’re fabricating parts for heavy-duty pipelines or intricate framework for buildings, a CNC plasma pipe cutting machine can handle the job with precision and speed.

What Are the Advantages of CNC Technology?

CNC technology offers significant advantages over manual pipe cutting methods and older machinery. Here are some of the key benefits:

- Precision – CNC controls allow for highly accurate cuts, reducing errors and the need for rework.

- Efficiency – Automated processes allow for faster production times, improving workflow and reducing labor costs.

- Consistency – CNC technology provides uniform results across all cuts, ensuring that each piece meets exact specifications.

- Complex cutting capabilities – With the ability to perform intricate cuts and angles, CNC plasma pipe cutting machines are ideal for projects that require detailed work.

- Reduced material waste – The accuracy of CNC technology helps reduce material waste, improving cost efficiency.

By integrating CNC plasma pipe processing machines into your fabrication process, you can enhance both the quality and the quantity of your output.

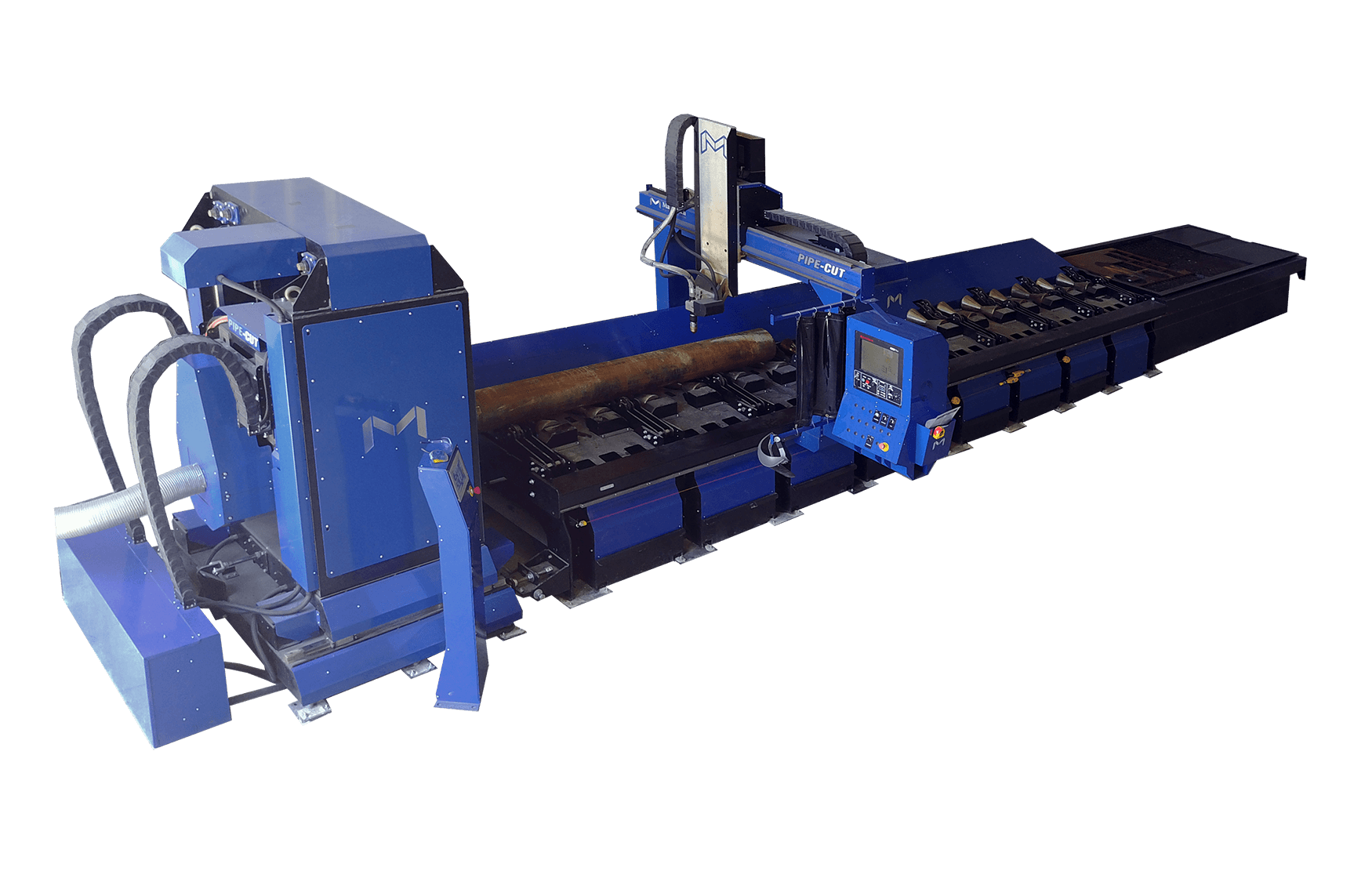

CNC Plasma Pipe Cutters from Machitech

Machitech offers advanced CNC plasma pipe cutting machines that can handle a wide variety of applications. The PipeCut SL, for example, is a powerful industrial pipe cutting machine designed for high-volume production. It features fully automated CNC controls, which improve cutting accuracy and reduce operator involvement, making it a great fit for large-scale industrial projects.

In addition, Machitech offers customizable CNC plasma pipe cutting machines that come with innovative features such as CNC controls from Hypertherm and automated rotary axes for precise pipe cutting. These machines are designed to work with a range of pipe diameters and lengths, giving you flexibility in your operations.

Maximize Your Fabrication Potential

Would you like to take your pipe cutting operations to the next level? Machitech offers state-of-the-art CNC plasma pipe cutting machines designed to improve precision, efficiency, and overall performance. Contact us today to learn more about how our machines can enhance your production capabilities.

English

English  Français

Français