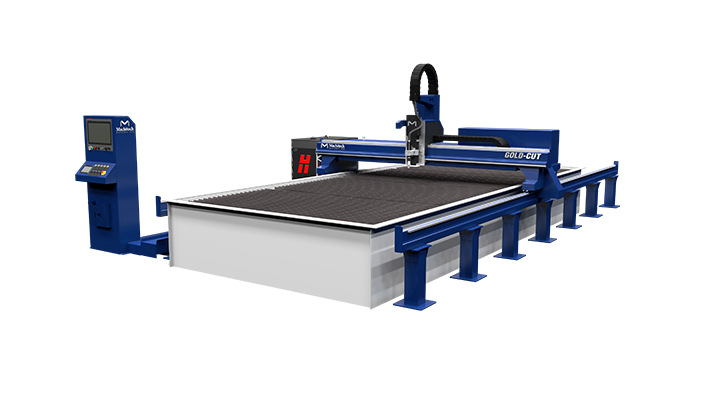

CNC Plasma Cutting Tables

Titanium Cut™

Heavy Plate Cutting, Drilling and Tapping

The Machitech Titanium Cut™ Plasma Table is a plate processing machine engineered for the most demanding customers such as Steel Service Centers, Ship Building and Structural Steel Applications. It's the perfect plate processing machine for high production volume & industrial drilling and tapping.

Request a pricing quote

Contact us to get a free custom quote

Request a pricing quote

Contact us to get a free custom quote

- 10’x20’ up to 30’x300’ (custom available)

- Heavy-Duty Gantry & Rails System

- 12”x12” Double Steel Gantry Fully Machined

- 40HP Drilling and Tapping Station

- Automatic tool changer (6 stations)

- Floor Mounted Inverted Rails System™

- Magnetic Torch Breakaway System

- Automatic Torch Height Controller

- Bosch Rexroth Servo Motor Drives

- Bosch Linear Ways on Machined surfaces

- Downdraft or Water Table (optional)

- Agma 10 Helical Rack & Pinion on all axis

- Ultra-precise Helical Planetary Gearboxes

- Oversized End-trucks

- Heat shield under gantry

- Cables and hoses are fully enclosed

- Hypertherm HPR400XD Plasma (Most Popular)

- Hypertherm HPR800XD Plasma

- Hypertherm XPR170 Plasma

- Hypertherm XPR300 Plasma

- Hypertherm Edge Connect™ Controller

- Hypertherm Pronest 2019 Software

- Machitech Industrial Enclosure

- 5-Axis Full Contour Bevel Head

- Up to 8 Oxyfuel Stations

- Additional Plasma Cutting Stations

- Fume extraction Systems

- Pipe and Tube Cutting systems

- Cut N'Clean Slag Removal System

- Removable trays for easy cleanout

- Electronic raise/lower system

- Digitizing tablets

- Manual Bevel System

- IHT Automatic Oxyfuel Torches

- Pneumatic scribe, inkjet or dot peen

- Additional security options

- Additional clearance under gantry

- Table Capacity: 8″

- Clearance Under Gantry: 12″

- Cutting Speed: 500 IPM (process)

- Max Speed Traverse: 1000 IPM

- Drilling Diameter: 3"

- Tapping Diameter: 1.5"

- Repeatability: 0.001″

- Positioning Accuracy: 0.002″

Features and Specifications

Top-of-the-line Standard Features

Available sizes: 10’x20’ up to 30’x300’ (custom available)

Gantry & Rails System, modular for expansion down the road

Double 12”x12” Heavy Duty Fully Machined Steel Gantry

Heavy Duty Construction for High Production needs

40HP Suhner Drilling and Tapping Station

6 station automatic tool changer

Magnetic Torch Breakaway System

Machitech Automatic Torch Height Controller

Bosch Rexroth AC Servo Motor Drives (Ethercat)

Innovative Patented Floor Mounted Inverted Rails System

Fully-welded and Machined tables (Downdraft or Water)

Oversized End-trucks for Maximum Stability

Agma 10 Helical Rack & Pinion on all axis

Bosch Linear Ways on Machined surfaces

Ultra-precise Helical Planetary Gearboxes

Heat shield under gantry to protect against heat

Cables and hoses are protected by an Enclosed Power Track

Why choose Machitech?

Full part list and electrical schematics

On-site installation and tailored training included

Free lifetime remote support

Hypertherm HPR400XD Plasma System

he HyPerformance® HPR400XD plasma system has been designed and built for maximum performance and productivity in x-y, bevel and robotic cutting operations. The versatile 400-amp rated system combines fast cutting speeds, rapid process cycling, quick changeovers and high reliability, and delivers the ultimate in HyPerformance mild steel cutting.

Other Plasma Systems Available

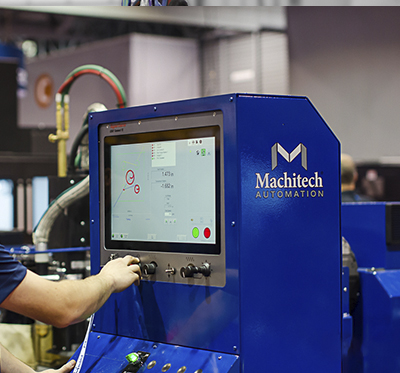

Hypertherm Edge Connect™ Controller

EDGE Connect is the next generation of Hypertherm’s industry leading automated control systems. This new platform is built upon 50 years of experience and commitment to develop, build, and sell products that improve your cutting operation.

Machitech Industrial Enclosure

Our self-standing industrial enclosure protects the controller against dust and impacts while providing hardware controls to the operator.

Available options for the Titanium Cut

5-Axis Full Contour Bevel Head

Additional Plasma Cutting Stations

Up to 8 oxyfuel stations

IHT Automatic Oxyfuel Torches

Fume extraction Systems

Pipe and Tube Cutting systems

Cut N’ Clean Slag Removal System

Removable trays for easy cleanout (waterbed)

Electronic raise/lower system (waterbed)

Digitizing tablets

Pneumatic scribe, inkjet or dot peen market

Security system (pull cord, light curtain)

Additional clearance under gantry

Featured options

Cut N’ Clean™ Slag Removal System

Camfil Dust Collectors

Machine Specifications

Table Capacity: 8″ (custom available)

Clearance Under Gantry: 12″

Cutting Speed: 500 IPM (related to process)

Max Speed Traverse: 1000 IPM

Drilling Diameter: 3″

Tapping Diameter: 1.5″

Repeatability: 0.001″

Positioning Accuracy: 0.002″

97%

of our customers

would recommend Machitech

Lifetime Remote Support

You need us? We're Ready. Anytime.

Photos and Videos

You might be interested in these solutions

Titanium Cut™

The perfect machine for steel service centers, ship builders & structural steel applications.

English

English  Français

Français