Metal pipe and tube fabrication can be a tricky business due to the rounded shape of the materials, which is more challenging to process than flat plates. This is particularly true when fabricating by hand. Professional fabricators who specialize in pipe and tube production should consider switching from handheld torches to CNC plasma pipe cutting, as the benefits in doing so can help improve the quality of their work, reduce cutting mistakes, and speed up production.

Precise Fabrications

When it comes to fabricating pipes and tubes, precision is integral to delivering a perfect product to the customer. CNC plasma cutters create pristine cuts on the first pass, eliminating the need for additional processing. Fabricators can trust that the cuts will be clean and free of errors.

Error-Free Cuts

Fabricating pipes or tubes by hand opens the door to cutting mistakes. Even the most experienced fabricators are not perfect and will make an error once in a while. But a computer-controlled pipe and tube cutter eliminates cutting mistakes altogether. In fact, with CNC software, a fabricator can easily identify and fix any issues that may lead to an error before the work begins.

Faster Turnarounds

By automating the fabrication process, CNC plasma pipe cutting machines can significantly speed up operations, ensuring production runs on schedule and freeing fabricators to move on to the next project. And because only one technician is needed to load and unload the materials, business owners can save on labor costs.

Fabricating Complex Shapes

CNC metal pipe cutters help expand fabrication capabilities by making easy work of complex shapes. Fabricating saddles, copes, miters, hillsides, and other unique profiles can be a challenging undertaking when working with a handheld torch. But a computer-controlled pipe and tube cutter ensures these parts are processed perfectly and allows fabricators to accept more complicated projects from their customers.

Improved Safety

Using handheld fabrication tools creates a health risk to employees and requires a range of safety precautions be put in place. CNC pipe and tube cutters, on the other hand, reduce these safety risks by minimizing material handling. The only human interaction CNC plasma pipe cutters require is setting up the profile in the CNC software, loading the material, and pressing the start button. The plasma torch remains safely out of reach throughout production.

User-Friendly Operations

Thanks to computer-controlled perfection, fabricating pipes and tubes has never been easier. In fact, most CNC plasma pipe cutting systems require little previous experience and minimal training for new employees, which can help fabricators save on onboarding costs.

Impressive Cost Savings

The cost savings earned by eliminated cutting mistakes, faster turnarounds, and a leaner workforce quickly add up, making a CNC plasma pipe and tube cutter a safe investment for professional fabricators looking to improve production at their shop.

The Leader in Industrial Cutting Solutions

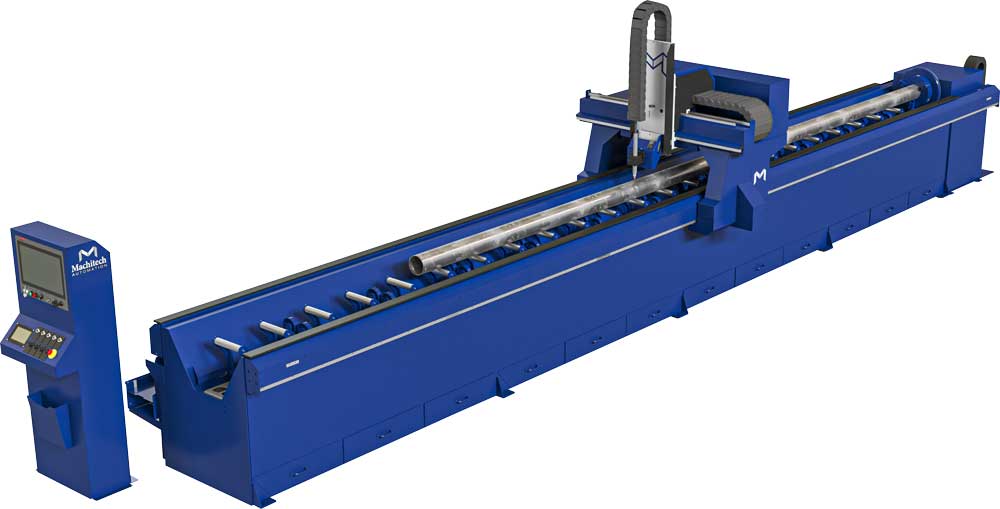

Machitech is the definitive authority on heavy-duty CNC plasma cutting tables and pipe/tube cutters. Our solutions are designed for custom fabrications and include free and unlimited support for life. Learn about our pipe and tube cutters by contacting us today.

English

English  Français

Français