When you decide to purchase a CNC plasma cutting system for your business it is usually no small investment. But, the large investment is sure to pay off in increased productivity and improved cut quality which ultimately leads to enhanced profitability. Most businesses that invest in a high-quality CNC plasma cutting system, such as a Machitech Automation CNC plasma cutting system, will experience a rapid ROI. But, if a CNC plasma cutting system is not well maintained with preventive maintenance, you may not see as fast of an ROI as you would otherwise. Any machine requires preventive maintenance to run effectively and efficiently without wearing down parts that diminish the overall life of the system.

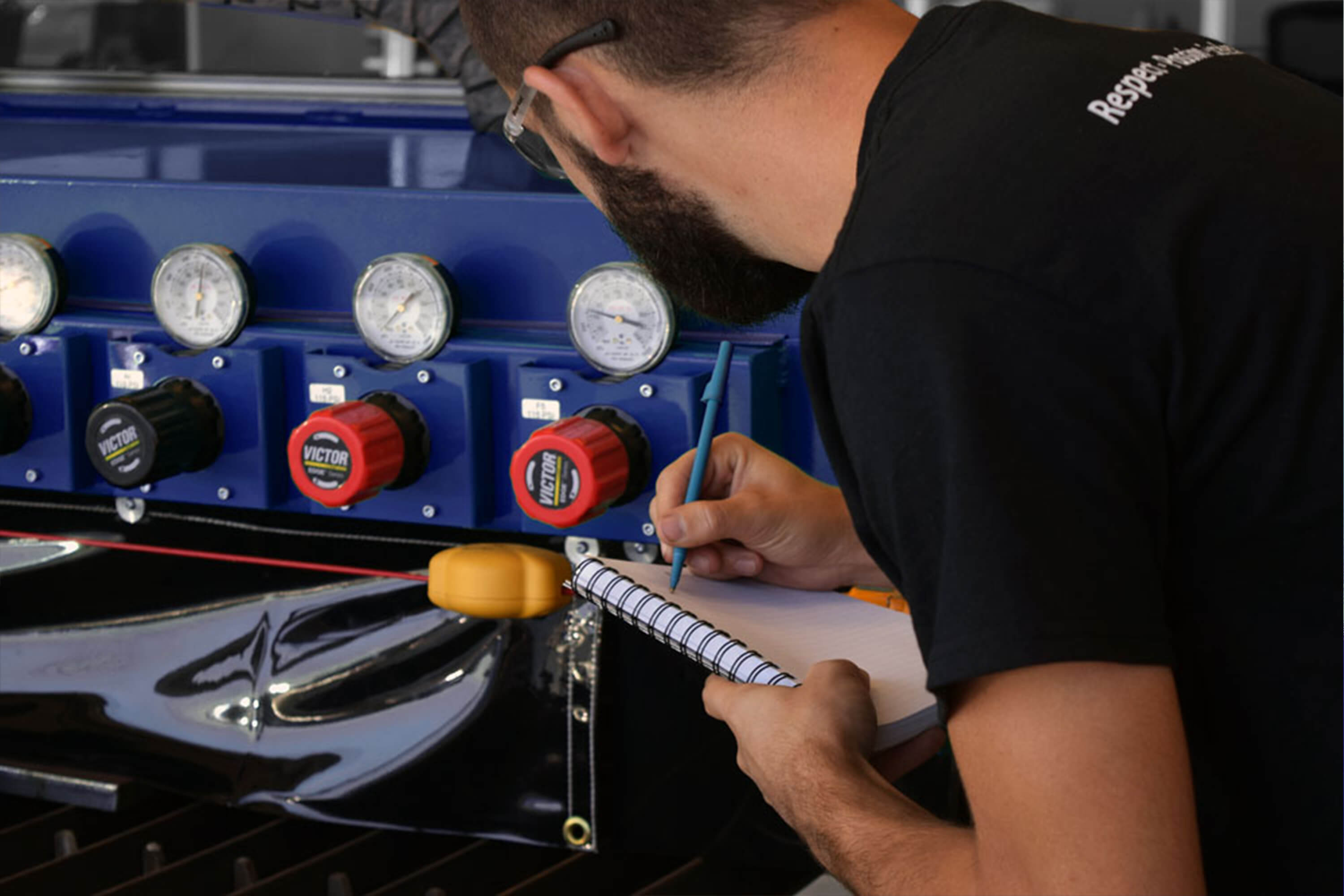

To best execute preventive maintenance for your CNC plasma cutting system, we recommend establishing a preventive maintenance schedule or calendar. That will help ensure that you stay on track and that nothing gets overlooked or forgotten altogether. First, it is best to schedule routine full system inspections. These inspections will help you ensure that you are looking at how the entire system functions so you have a good idea of when things are beginning to wear out or need repair. There are many ‘common wear’ items such as consumables or other parts that will need to be routinely replaced. By keeping that on the schedule you will not risk wearing out things and damaging your system or having it run inefficiently/ineffectively. In fact, rather than burning out consumables, if you routinely replace common wear items you will actually maximize the life of your consumables.

As Fabricating and Metalworking points out, you should not wait until you notice a problem to maintain your CNC plasma cutting system, “Perhaps the old adage “the squeaky wheel gets the grease” proves true here. Plasma cutting systems – at least good, quality systems – typically don’t tend to be troublesome. Instead, they go about the job day in and day out, slicing through whatever metal is thrown at them. But even though your plasma system may appear to work just fine, failing to properly maintain this machine is quietly impacting its functional performance and life. Eventually over time, its mechanical parts will start to wear and cause rough machine motion. Part tolerances will deviate. Cut quality, particularly at higher speeds, will suffer.” Your CNC plasma table and plasma torch manufacturer should have maintenance guidelines and instructions for how often to perform preventive maintenance as well as how to do so. Routine preventive maintenance helps reduce the chance of needing emergency repairs or experiencing unexpected downtime that will slow production and could impact profitability.

English

English  Français

Français