Efficient stainless steel fabrication is crucial for businesses that rely heavily on high-quality metal components. The cutting process needs to be both efficient and precise, and taking advantage of advanced technology can help these businesses maximize their production capabilities while maintaining the integrity of stainless steel’s unique properties.

Unique Properties of Stainless Steel

Stainless steel is a preferred material in metal fabrication. One of its most notable characteristics is its resistance to corrosion, which is achieved through the addition of chromium. This makes stainless steel particularly suitable for environments where exposure to moisture and chemicals is common. Additionally, stainless steel boasts impressive strength and durability, allowing it to withstand heavy loads and extreme conditions. Its aesthetic appeal, characterized by a sleek and modern look, further contributes to its popularity, especially in industries where appearance matters just as much as function.

Industries That Rely on Stainless Steel Fabrication

Many industries depend on stainless steel fabrication for creating high-performance products. Some examples include:

- Food and beverage – Stainless steel is used in the production of food processing equipment, kitchen appliances, and storage containers due to its hygienic properties.

- Healthcare – Surgical instruments, medical devices, and hospital fixtures are often made from stainless steel because it is easy to sterilize and maintain.

- Construction – Stainless steel is a key material in architectural designs, structural components, and building facades due to its strength and resistance to weathering.

- Automotive – Exhaust systems, trim, and various under-the-hood components are often fabricated from stainless steel due to its durability and heat resistance.

Benefits of Using Stainless Steel in Metal Fabrication

Why is stainless steel such a popular option in metal fabrication? Here are some factors that make it appealing:

Longevity

Stainless steel’s inherent strength makes it an excellent choice for applications that demand long-lasting performance. It can withstand significant wear and tear, making it ideal for products that are subject to heavy use.

Corrosion Resistance

The corrosion resistance of stainless steel ensures that products maintain their integrity over time, even when exposed to harsh environments. This characteristic reduces the need for frequent replacements or maintenance.

Aesthetic Appeal

The sleek and polished look of stainless steel adds a modern touch to any product or structure, making it a favorite in both industrial and consumer markets.

Strength

Stainless steel offers a superior strength-to-weight ratio, making it possible to create robust yet lightweight structures and components.

Heat Resistance

Stainless steel can withstand elevated temperatures, making it suitable for applications involving extreme heat, such as in the automotive and aerospace industries.

Ease of Fabrication

Despite its strength, stainless steel is relatively easy to fabricate, allowing for the creation of complex shapes and designs without compromising its structural integrity.

Sustainability

Stainless steel is 100% recyclable, making it an environmentally friendly option for businesses looking to reduce their carbon footprint.

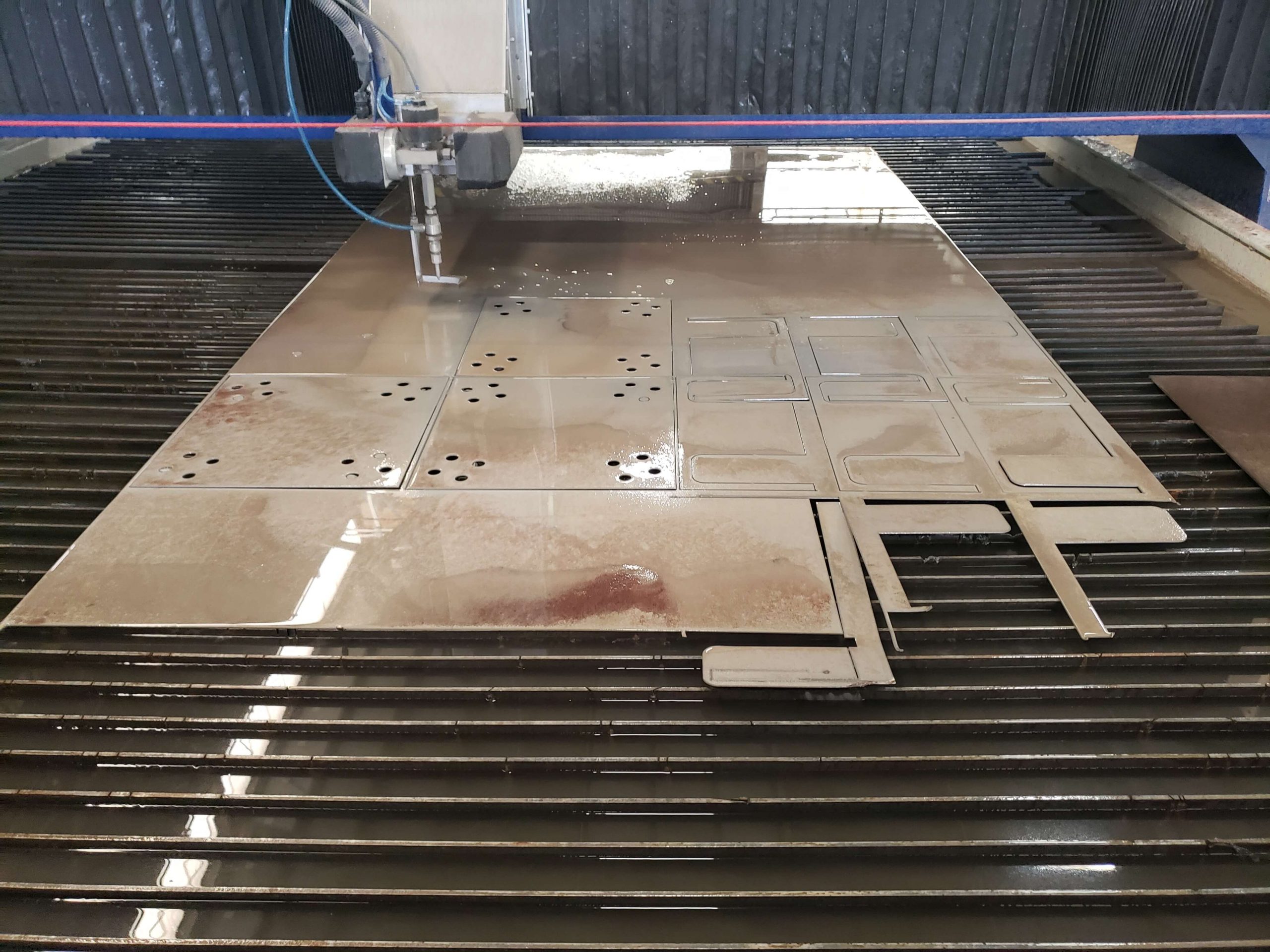

Why CNC Plasma Cutters Are Ideal for Stainless Steel Fabrication

CNC plasma cutters are an excellent choice for stainless steel fabrication due to their precision and efficiency. A CNC plasma cutter operates by directing a high-velocity jet of ionized gas (plasma) at the material, which melts the metal and allows for clean, accurate cuts. This technology is particularly advantageous for stainless steel, as it minimizes heat distortion and ensures consistent results, even with complex designs.

CNC Plasma Cutters From Machitech

Machitech offers a range of CNC plasma cutters designed to meet the diverse needs of industrial and commercial businesses. From the Machitech Silver Cut to the Machitech Platinum Cut, these machines provide unparalleled precision, speed, and reliability. Each model is engineered to handle the demands of stainless steel fabrication, ensuring that businesses can produce high-quality components efficiently.

Upgrade Your Stainless Steel Fabrication

Investing in a Machitech CNC plasma cutter is a smart move for any business that values precision, efficiency, and durability. To learn more about how our CNC plasma cutters can enhance your stainless steel fabrication process, contact Machitech today.

English

English  Français

Français