Every shop that depends on metal fabrication is looking for ways to improve efficiency and productivity, so they must stay in tune with the latest trends and advancements. And while there are always new metal fabrication options available on the market, they’re often met with skepticism and dogged by myths about their value and functionality. One example of this is the combination of plasma cutting and drilling machines, which represent a significant advancement but are hindered by misbeliefs that have made some businesses hesitant to adopt this technology. Understanding the true capabilities of these machines can illuminate their potential.

What is a Plasma machine and Drilling combo?

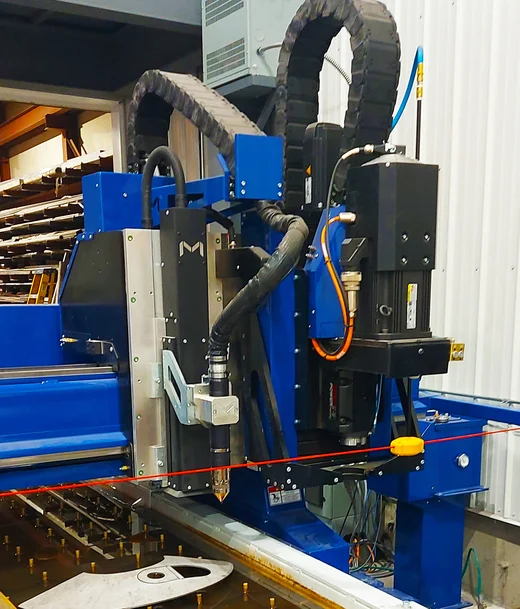

It is as simple as it sounds! A plasma cutting system that combines a drilling system into a single machine. Adding drilling capabilities allows for more complex operations to be completed seamlessly within the same setup. This multi-functional approach enhances the efficiency of metal fabrication task.

What are the benefits of getting this combo?

SAVES TIME AND MONEY

While a drill may add cost to your machine upfront, the long-term cost savings when it comes to labor and secondary processing will certainly outweigh the investment.

In most scenarios, an operator will cut out a single part with either a plasma spot mark or have to lay the part out manually. Once complete, they will walk the part from the cutting machine over to a drill press or mill to create the hole. The operator loads the drill bit in, drills the part, then walks back to the cutting machine or wherever the part will be stored. A slight savings is noticed if the customer cuts and drills multiple parts out per nest.

In a drill machine scenario, the part is created in the office with the drilled hole location set. Once sent to the machine, it simply runs the program normally, drills the hole, cuts the part and at the end of the cycle – the operator unloads a finished

part. Depending on how far the drill station is from the machine, this could save 5-10 minutes per part!

UNDERSIZE HOLES

A general rule of thumb for plasma is a 1:1 ratio hole. If you’re cutting ¾” plate, the minimum hole size you can cut (that will come out straight and not tapered) is ¾” OD. A drill removes this limitation so you can effectively cut any diameter hole in any thickness plate (provided your tooling is correct). This capability enables customers to bid and win more jobs – we’re removing machine limitations while also cutting down labor cost.

TAPPING HOLES

Plasma cut hole cannot be tapped directly off the machine. A combination of work hardening and hole taper makes this an impossible task and if it is achieved, the wear and tear on a tap will be exponentially more than a normally drilled hole. Not only can we drill the hole, but we can also tap the hole on the machine. Again, the operator is cutting out an entire step, saving time, and picking up finished parts from the machine.

ELIMINATES REWORK AND HUMAN ERROR

The machine will drill and cut exactly where you tell it to. If an operator or laborer is expected to layout holes, drill holes, then tap holes – there is always going to be a factor of error. We are completely eliminating that factor of error after the design phase, ensuring that rework costs are kept at a minimum.

OPENS UP NEW LINES OF WORK

There are plenty of industries that require drilled holes and do not allow thermally cut holes. This investment opens shops up to new jobs, new customers, and new growth.

Machitech’s Combination Systems

Machitech offers this combo option in many of their plasma machines: the Diamond Cut, Platinum Cut, and Titanium Cut. Each model offers unique drilling options to suit different industrial needs, whether it’s high-speed precision or heavy-duty performance.

With more than 20 years of experience and more than 2,000 machines installed globally, Machitech is a trusted leader in CNC plasma cutting systems.

Learn more about the features and options available on each of our combination models:

Need further information?

If you need further information on the Plasma and Drilling combo, send us a request and a customer representative will contact you shortly.

Contact Machitech today to schedule a consultation.

English

English  Français

Français